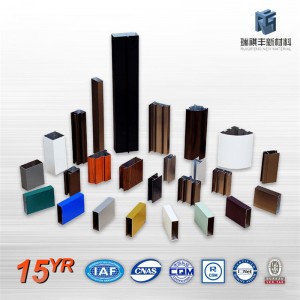

Aluminium Profiles For Windows And Doors

Aluminium Profiles For Windows And Doors

Aluminium Profiles For Windows And Doors,

Aluminium Profile,

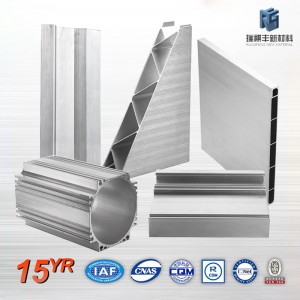

Extruded heat sinks are also known as heat sink extrusion or extruded aluminum heat sink, heat sink extrusion with beautiful appearance, lightweight, good heat dissipation performance, energy-saving effect. Simply put, aluminum heat sink extrusion technology is to heat aluminum ingots to 520~540℃ at high temperature, under high pressure to let the aluminum liquid flow through the heat sink extrusion mould with grooves, to make the extruded heat sink material. Then, the extruded aluminum heat sink we often see is made after cutting and cutting the heat sink extrusion material. Aluminum heat sink extrusion technology is easy to realize, and the cost of equipment is relatively low, so it has been widely used in the low-end market in previous years. AL6063 is a commonly used aluminum heat sink material with good thermal conductivity and machinability.

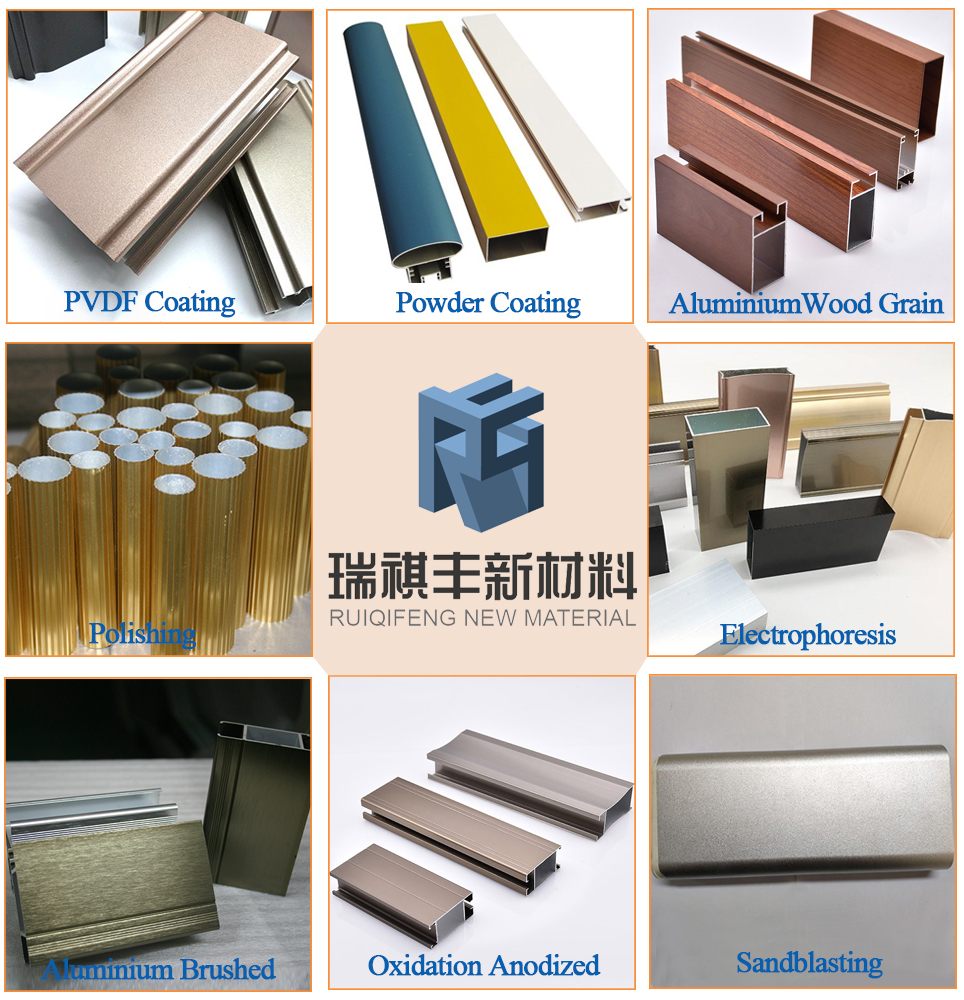

Ruiqifeng relying on long-term accumulated technical experience and production process sets aluminum alloy profiles with good thermal conductivity and other characteristics and develops a customized aluminum extruded heat sink that can meet customers’ requirements of product differentiation, specialization and personalization. The finished extruded heat sinks surface is anodized to improve the corrosion resistance, wear-resistance and appearance of aluminum. At present, the commonly used types of extruded aluminum heat sink in China are electronic heat sink, computer heat sink, sunflower heat sink, power semiconductor heatsink and so on. Because of their superior performance, extruded aluminum heat sinks are widely used in machinery, automobile, wind power, construction machinery, air compressor, railway locomotive, household appliances and other industries.

Extruded heat sinks are generally high power heat sink and cooling systems. Ruiqifeng thermal can provide reliable natural convection environment solutions according to the existing mature technology of extruded aluminum heat sink. Aluminum heat sink extrusion moulding can be achieved through the mould, which can realize the complex structure of the heat sink fin. These complex radiating fins make the radiating surface area more prominent and reduce the cost and time of aluminum processing.

The main advantages of aluminum extruded heat sinks are as follows:

1. More efficient than stamping heat sink

2. More cost-saving than mechanical processing

3. There are a variety of standard shapes and sizes

4. Easily customized than copper lighter, obvious advantage

Guangxi Ruiqifeng New Material Co., Ltd.

Add: Pinggou Industrial Zone.Baise, Guangxi, China.

Tel: 86-776-5608888

Fax: 86-776-5608666 P.C.: 531499

Sales Center(Nanning)

Add: 1709, 21 Pingle Avenue, Liangqing District, Nanning, Guangxi

Mob: 0086-13556890771

E-mial: info@aluminum-artist.com

www.aluminum-artist.com (English) www.pgjf.com(Chinese)

As we all know, the economy is not very good this year, and raw materials are rising rapidly, so many companies will face the pressure of cost. However, we are in the resource place of bauxite, and we get the high quality liquid aluminum from the CHALCO, besides, we have the melting&casting workshop, mold manufacturing center, extrusion factory, and deep processing plant. All of these favorable factors mean we could provide you with more competitive prices, one-stop service, and guaranteed quality.

If not sure which item is right for you? please don’t hesitate to contact Ruiqifeng Technical, or directly call us at +86 13556890771, or request an estimate via Email (info@aluminum-artist.com).