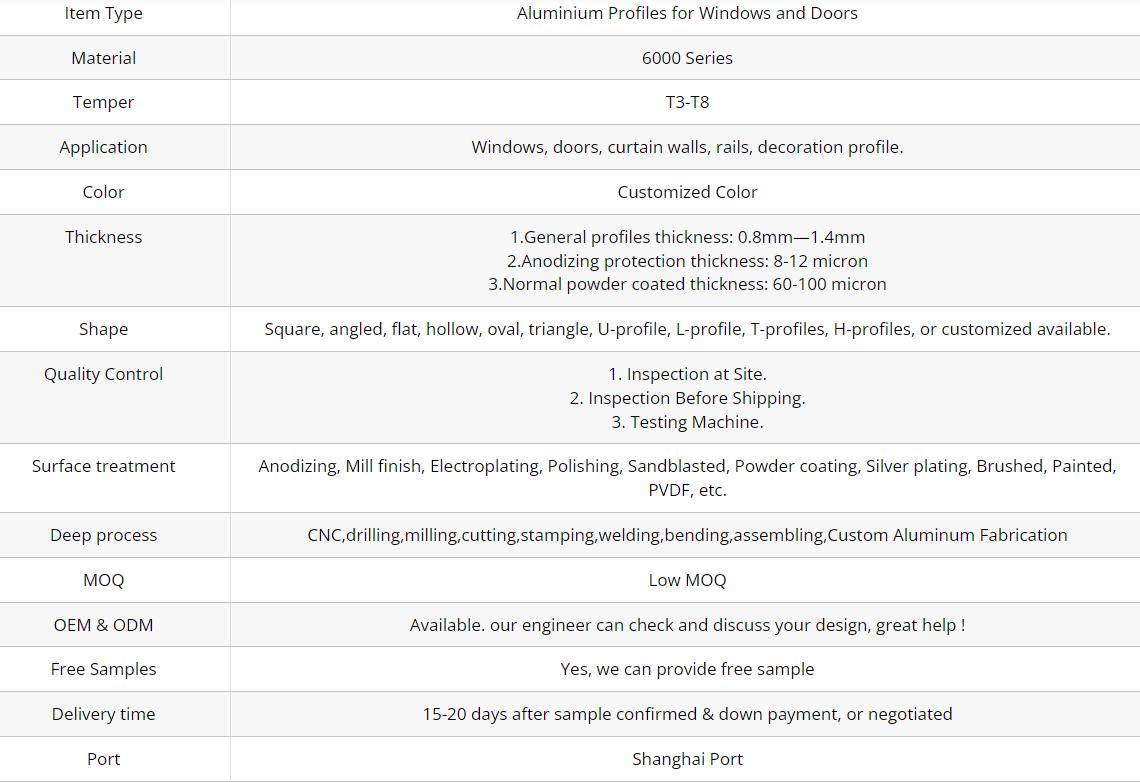

Aluminium Profiles for Windows and Doors

Aluminium Profiles for Windows and Doors

Product Introduction

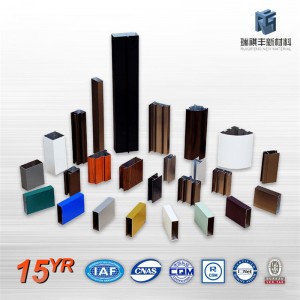

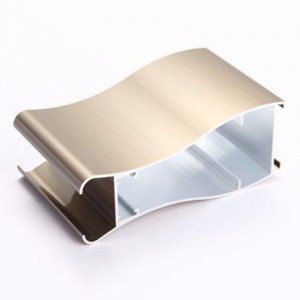

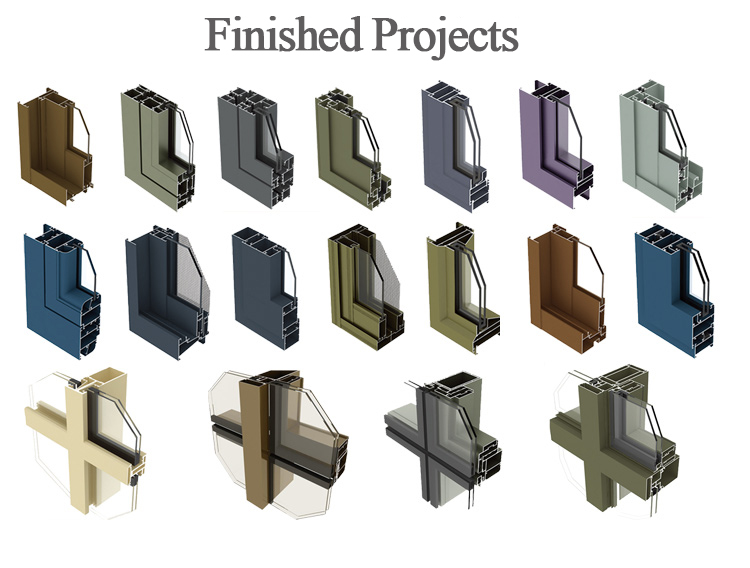

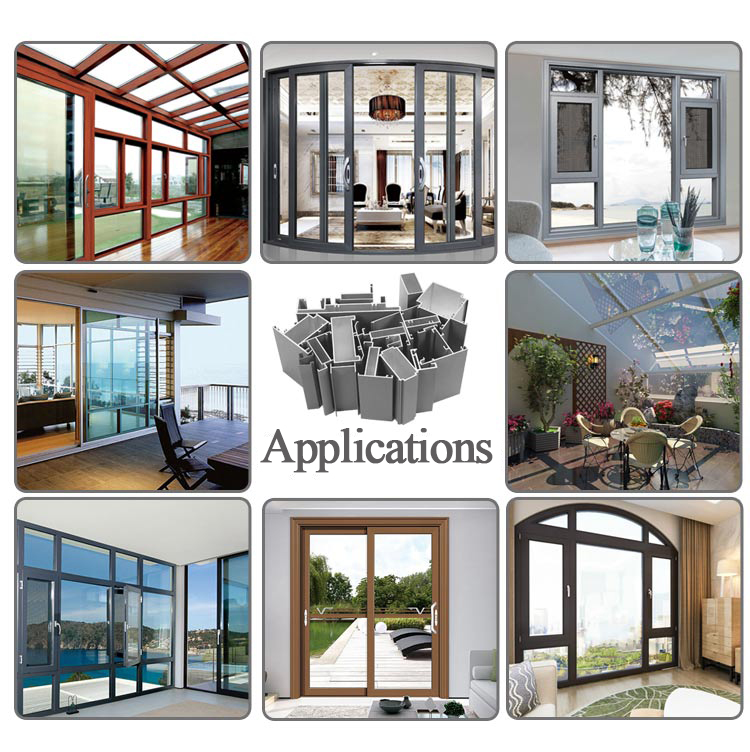

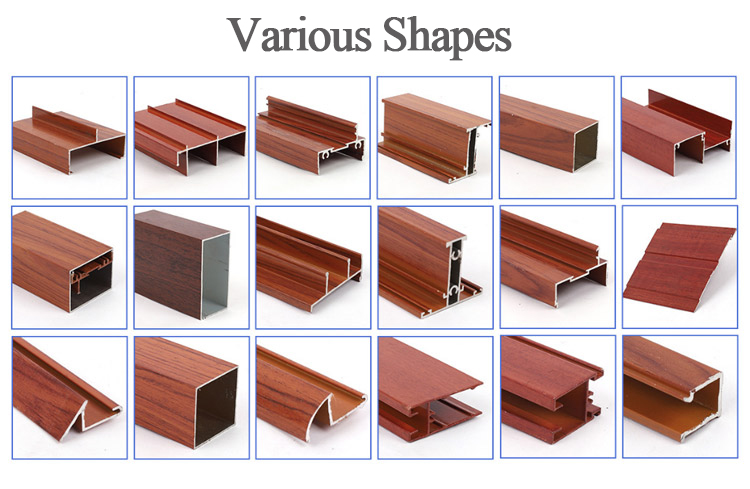

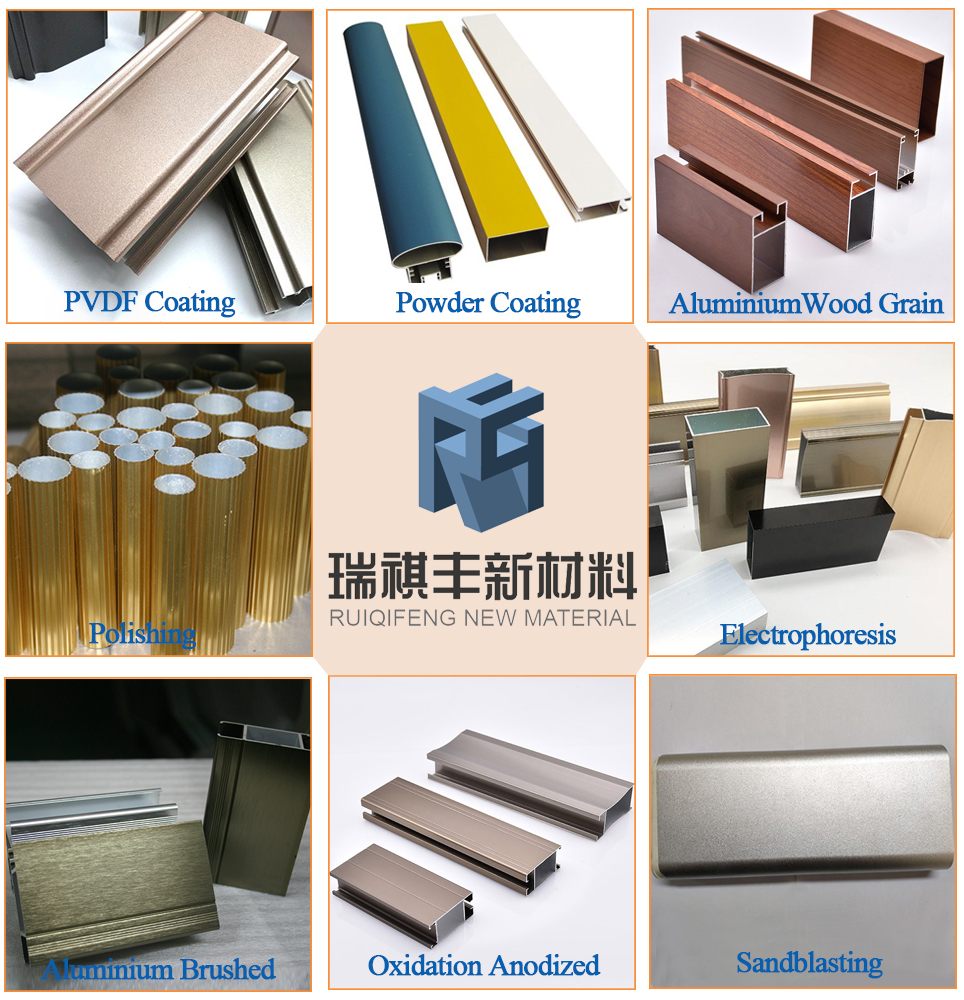

Aluminum profile with surface treatment can be used widely as the material of window and door and commercial partition. Aluminium window and door from Ruiqifeng Aluminium can be produced in different finishes for different purposes indoor and outdoor. All surface treatment techniques aim at improving the durability and ornament of the aluminum profile. As a professional aluminium window supplier and aluminium door supplier, we provide aluminium window and door of different sizes, and different selections on aluminum profile finish to embrace the complete satisfaction of our customers.

Process Introduction

With more than 20 years development, Ruiqifeng have already built a much experienced and professional team and a complete supply chain.

Advanced Produce Equipment

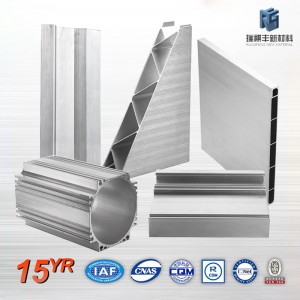

We have advanced fully automated production lines, powder coating lines, anodized production and wooden grain lines.

Here, you can always find the right surface treatment you want.

Also, Our production process conforms to the ISO9001 standard and gets the Qualicoat already.

We can control the corresponding quality standards to ensure your satisfaction according to different market requirements, from the thickness to cutting length.

Aluminium Profiles for Windows and Doors

Ruiqifeng aluminium profiles for windows and doors are produced by the latest extruded technology, which can be used much longer lasting and durable than the vinyl window frame, additionally, it has many various and more colorful surface finishes for you choose.

● 99.7% Pure & High-Grade Aluminum Ingot Raw Material

● In-house Strictly Testing Lab for 6-step internal inspection

● 35 extrusion lines guarantee your delivery on time

● Customized your own design with our latest Tooling Technology

Your Reliable Aluminium Profiles for Windows and Doors Supplier

Ruiqifeng aluminium profiles for windows and doors are made of Aluminum 6063 Alloy Number, it is the most common alloy number for producing aluminum window and door profile. 6063 aluminum alloy is widely used in building aluminium window extrusions and aluminum profiles doors, It has good surface decoration after Powder coated surface treatment. And it has good corrosion resistance.

Powder Coating is by far the most popular used in commercial and residential aluminium doors and windows. Powder coated aluminum windows have a top feature that makes the window clean, durable, weather-resistant, and comes in a variety of colors. The most common is the RAL color which has about 200 standard colors.

Beside powder coated finishing, Ruiqifeng has anodizing (polishing, brushed), PVDF, and electrophoresis coating as well.

The common use package of aluminum profiles

1. Ruiqifeng Standard Packing:

Stick the PE protective film on the surface. Then the aluminium profiles will be wrapped into a bundle by the shrink film. Sometimes, the customer asks to add a pearl foam inside cover the aluminium profiles. Shrink film can have your logo.

2. Paper Packing:

Stick the PE protective film on the surface. Then the number of aluminium profiles will be wrapped into a bundle by the paper. You can add your logo to the paper. There have two options for paper. Roll of Kraft paper and straight Kraft paper. The way of using of two kinds of paper is different. Check the picture below you will know it.

3. Standard packing + Cardboard box

The aluminium profiles will be packed with the standard packing. And then pack in the carton. Last, add the wooden board around the carton. Or let the carton load the Wooden pallets.

4. Standard Packing + Wooden Board

First, it will be packed in standard packing. And then add the wooden board around as the bracket. In this way, the customer can use the forklift to unload the aluminium profiles. That can help them save the cost.

However, they will change the standard packing to reduce the cost. For example, they just need to stick to the PE protective film. Cancel the shrink film.

Here are a few points to note:

a. Every wooden strip is the same size and length in the same bundle.

b. The distance between the wooden strips must be equal.

c. The wooden strip must be stacked on the wooden strip when loading. It cannot be directly pressed over the aluminium profile. This will crush and smear the aluminium profile.

d. Before the packing and loading, the packing department should calculate the CBM and weight first. If not it will waste much space.

Below is the picture of the correct packing。

5. Standard Packing + Wooden Box

First, it will be packed with standard packing. And then pack in the wooden box. There also will have a wooden board around the wooden box for the forklift. The cost of this packing is higher than the other one. Please notice that there must have foam inside the wooden box to prevent the crash.

The above is just the common packing. Of course, there are many different packing ways. We appreciate hearing your requirement. Contact us now.

Loading & Shipment

As we all know, the economy is not very good this year, and raw materials are rising rapidly, so many companies will face the pressure of cost. However, we are in the resource place of bauxite, and we get the high quality liquid aluminum from the CHALCO, besides, we have the melting&casting workshop, mold manufacturing center, extrusion factory, and deep processing plant. All of these favorable factors mean we could provide you with more competitive prices, one-stop service, and guaranteed quality.

If not sure which item is right for you? please don’t hesitate to contact Ruiqifeng Technical, or directly call us at +86 13556890771, or request an estimate via Email (info@aluminum-artist.com).