Automobile Industry

The rapid growth of electric and hybrid vehicles has led to a significant shift in the automotive industry towards new energy vehicles (NEVs). Amid this transition, aluminium has emerged as a critical material in the development and production of NEVs.

Lightweight Construction

One of the most impactful advantages of aluminium in NEVs is its lightweight nature. Aluminium is significantly lighter than traditional steel, enabling automakers to reduce the overall weight of vehicles without compromising structural integrity or safety. By utilizing aluminium in the construction of frames, chassis, and body panels, NEVs can achieve higher energy efficiency and longer driving ranges due to reduced weight. Additionally, lighter vehicles require smaller and lighter battery packs, resulting in improved performance and increased passenger comfort.

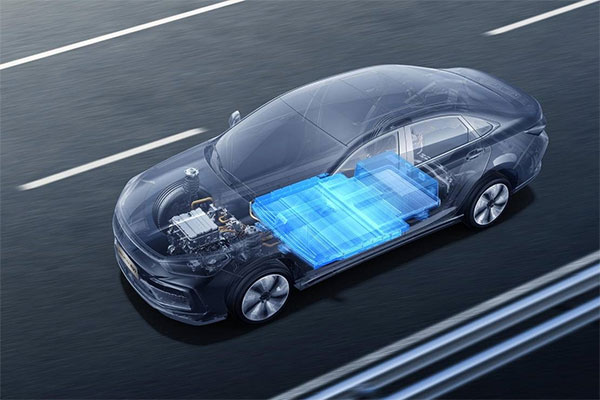

Battery Enclosures

Aluminium's high strength and excellent heat dissipation properties make it an ideal choice for battery enclosures in NEVs. Batteries are a vital component of electric vehicles, and their proper functioning and thermal management are crucial. Aluminium enclosures provide superior heat dissipation, ensuring that batteries operate within their optimal temperature range. Moreover, aluminium's lightweight and corrosion-resistant qualities contribute to extended battery life and overall vehicle performance.

Energy Efficiency

Aluminium's application in NEVs extends beyond the physical structure of vehicles. It also plays a significant role in enhancing energy efficiency. For instance, aluminium is utilized in electric motor casings, which not only provide protection but also aid in dissipating heat generated during operation. This helps optimize motor performance and increases the overall efficiency of the vehicle. Additionally, aluminium's electrical conductivity improves power transfer, leading to reduced energy loss and increased efficiency of electrical systems.

Sustainability and Recyclability

Aluminium is widely recognized for its sustainability and recyclability. Unlike other metals, aluminium can be recycled repeatedly without losing its original properties, significantly reducing the environmental impact of NEV production. The recycling process for aluminium requires only a fraction of the energy used in primary production. Furthermore, the lightweight nature of aluminium contributes to reduced energy consumption during vehicle operation and lower emissions, consequently promoting a greener transportation ecosystem.

Design Flexibility

Another advantage of aluminium in NEVs is its design flexibility. Aluminium can be easily shaped and molded into various forms, allowing automakers to create innovative and aerodynamic vehicle designs. This flexibility makes it possible to optimize the efficiency and aerodynamics of NEVs, resulting in improved range capabilities and reduced drag.

Aluminium's wide-ranging applications in new energy vehicles are reshaping the automotive industry and accelerating the transition towards sustainable transportation. From lightweight construction to battery enclosures, aluminium's unique properties contribute to improved energy efficiency, longer driving ranges, and enhanced performance. The material's recyclability and design flexibility further reinforce its role in promoting a greener future. As the demand for NEVs continues to surge, aluminium's presence in the automotive sector will play a pivotal role in driving the adoption of sustainable transportation worldwide.