Big discounting Copper Heat Pipe - High Power IGBT Aluminium Heat Sink – Ruiqifeng

Big discounting Copper Heat Pipe - High Power IGBT Aluminium Heat Sink – Ruiqifeng

Big discounting Copper Heat Pipe - High Power IGBT Aluminium Heat Sink – Ruiqifeng Detail:

Motor controller Insulated Gate Bipolar Transistor (Insulated Gate Bipolar Transistor, the IGBT) heat dissipation performance increasingly become motor IGBT now entering the industrial power electronics market, such as (welding) heat sink, traction inverter, motor drive, etc. Ruiqifeng provides IGBT heat sink assembly products that allow IGBT to work at a higher temperature enclosure while keeping the working junction temperature within a safe range by combining low thermal resistance with Vce(on) silicon.

IGBT in most cases works with a high power device, high power means higher heat dissipation, IGBT is toward large capacity, high frequency, easy to drive, low loss, modular, points out the direction of development, compared with other power electronic devices, IGBT heat sink has high reliability, simple drive, easy to protect, there is no buffer circuit and switching frequency is high, so the IGBT heat sink in the electronic market becomes very necessary. In order to achieve these high performances, many processes are used in integrated circuits, such as epitaxy, ion implantation, fine lithography, etc. In recent years, the performance of the power IGBT module heat sink has been improved rapidly, the rated current has reached hundreds of amperes, the withstand voltage of more than 1500V, and is still improving. Since IGBT devices have positive characteristics of the PIN diode, the characteristics of the p-channel power IGBT module heat sink are not much different from that of n-channel IGBT, which is very conducive to adopting a complementary structure in the application, thus expanding its application in the field of ac and digital control technology. The biggest advantage of IGBT is that it can withstand current shock in either an on or short circuit state. Its parallel connection is not a problem and its series connection is easy due to its short shutdown delay.

IGBT heat transfer modes usually include air cooling, water cooling, copper heat sink or aluminium heat sink. Its heat dissipation is based on the basic principle of heat transfer, a heat flow path with the lowest thermal resistance is designed for the device so that the heat emitted by the device can be emitted as soon as possible, so as to ensure that the internal junction temperature of the device is always kept within the allowable junction temperature.

At present, the existing IGBT heat pipe heat sink in the market mainly includes heat dissipation fin, heat pipe and substrate, on which the substrate is provided with a number of parallel grooves, and then the groove is welded with solder to the evaporating section of the heat pipe. In the existing IGBT heat pipe heat sink technology, the evaporating section of the heat pipe is buried in the groove of the substrate and does not directly fit the IGBT surface. In the working process, the heat from the IGBT surface is firstly exported through the substrate and then transferred to the heat pipe and heat sink. Finally, the heat from the heat sink is transferred to the air by convection. Because the substrate itself has thermal resistance, and the thermal conductivity coefficient of the heat pipe is much higher than that of the base, the thermal conductivity efficiency of the heat pipe heat sink is limited, and the heat dissipation performance is reduced. IGBT heat sink can transfer the heat evenly from the substrate to the fin, which can effectively solve the heat dissipation problem of high heat flux, not only with high efficiency but also with a compact structure and no moving parts, which can truly realize maintenance-free.

High Power IGBT Heat Sink With Friction Welding Technology

| Place of Origin: | Guangxi | OEM: | Yes |

| Process: | Aluminum extrusion + Friction Welding | Temper: | T3-T8 |

| Material: | Aluminium Profile | Shape: | Square |

| Packing: | Standing Export Packing | Brand Name: | Ruiqifeng |

| Application: | IGBT | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | RQF005 | Tolerance: | 0.01 mm |

| Finish: | Clean+Anodized | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | 400*300*100 mm |

Product Process

The IGBT heat sink is adopted the friction welding process, the two pieces of aluminum heat sink friction welding together, so as to achieve the IGBT heat sink need cross section, Finally, the integrated appearance structure and uniform heat dissipation performance are formed after CNC processing, the friction welding process can reduce the cost of the mould, cycle time is long, high stability. Lori has developed a variety of standard aluminum heat sink materials and continuously enhanced the standard materials database to provide customers with more joint solutions to choose from. The IGBT heat sink processing process is as follows

IGBT heat sink with heat pipe

Product Details

This IGBT heat sink with heat pipe mainly included heat sink fin, heat pipe and base, wherein the base is provided with a number of mutually parallel grooves, the grooves are then soldered with solder to the evaporating section of the heat pipe

In the existing IGBT heat sink with heat pipe technology, the evaporating section of the heat pipe is buried in the base groove, which does not directly fit with the base of IGBT. During the IGBT working process, the heat on the surface of IGBT is firstly dissipated through the base, and the heat then transferred to the heat pipe and heat sink fin. Finally, the heat is transferred to the air by convection through the heat sink fins.

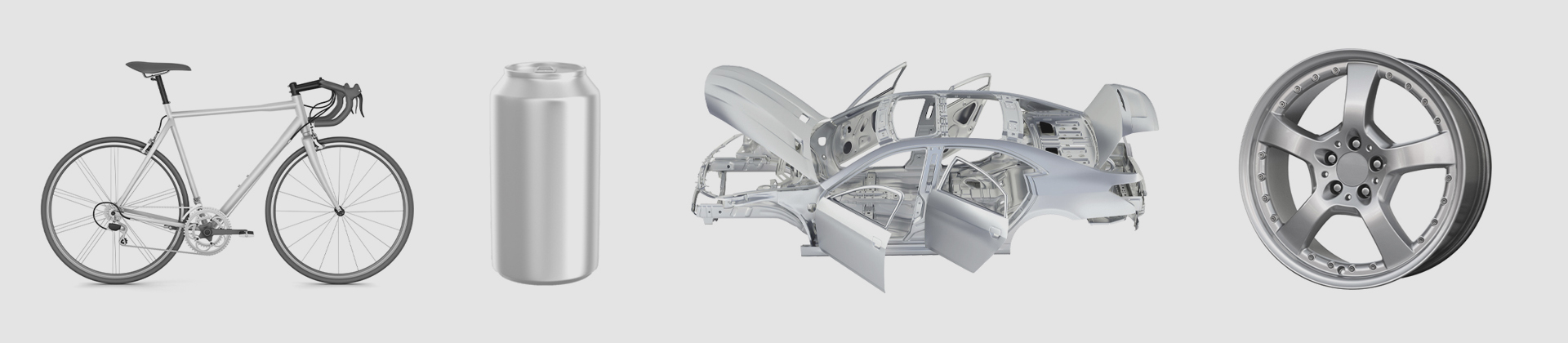

IGBT Heat sink Application

| Place of Origin: | Guangxi | OEM: | Yes |

| Process: | Profiles Extruding | Temper: | T3-T8 |

| Material: | AL 6063 T5 | Shape: | Square |

| Packing: | Standing Export Packing | Brand Name: | Reqifeng |

| Application: | IGBT inverter | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | RQF005 | Tolerance: | 0.01 mm |

| Finish: | Anodizing | Quality control: | 100% thermal test |

| Extra process: | Cutting + CNC Machining(Milling, Drilling,Tapping) | Size: | 142(W)*71.5(H)*200(L)mm, or custom design |

| Max Aspect Ratio | More than 20 times aspect ratio heat sink can be extruded by 800 tons–5000 tons extruding machine by the most advanced technology | ||

| Max Width | Ultra wide extruded heat sink can be made by our unique friction welding technology | ||

| Sample Service | Samples with differernt sizes are availabe for prototypes test within 1-2 week | ||

| Production Process | Aluminum base —Cutting—CNC Machining(Milling, Drilling,Tapping), Deburring, Cleaning, Inspecting, Packing | ||

IGBT Heat Pipe Heat sink applied to LEDLighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems,etc.

Product detail pictures:

Related Product Guide:

Ruiqifeng New Materials Co., Ltd. is a well-known profile aluminum supplier, specializing in profile aluminium extrusion production with nearly 20 years of experience. Our factory is headquartered in Pingguo, Guangxi, with a superior geographical location and rich aluminum ore resources. This advantageous position enables us to offer high quality profile aluminium at competitive raw material prices. Equipped with advanced production technology, our company is committed to becoming a leading exporter of first-class profile aluminium. As a comprehensive service provider, we provide a complete solution, including design, mold making, production, transportation and after-sales support. Our experienced sales team will work hard to meet your requirements throughout the entire process to ensure you receive a satisfactory solution. We offer a variety of aluminium profiles, including architectural profiles, industrial aluminium profiles, decorative profiles, and more. Customization is at the core of our services, as we aim to meet the unique needs of different projects based on our clients' specific requirements. Our products are of excellent quality, reliable performance and beautiful design. They undergo strict quality control and testing procedures to ensure compliance with industry standards and exceeding customer expectations. Richifeng is driven by the pursuit of excellence and innovation. We continuously invest in research and development to enhance our product processes and technologies to adapt to the changing needs of the market. Over the years, we have established mutually beneficial cooperative relationships with many well-known companies, providing them with high-quality aluminum frame products and winning a good reputation and trust. Integrity, quality and innovation are the guiding principles of our operations. We strive to grow and develop together with our esteemed customers. Through our dedicated efforts and collaborative spirit, we aim to provide our customers with quality aluminum framing products that contribute to the success of their projects. If you have any interest in our products or have any questions, please feel free to contact us. We eagerly look forward to the opportunity to cooperate with you and create a better future together! Big discounting Copper Heat Pipe - High Power IGBT Aluminium Heat Sink – Ruiqifeng , The product will supply to all over the world, such as: Rwanda, Philippines, Netherlands, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!