China OEM China New Enery Vehicles Battery Tray of Alunimum Extrusion

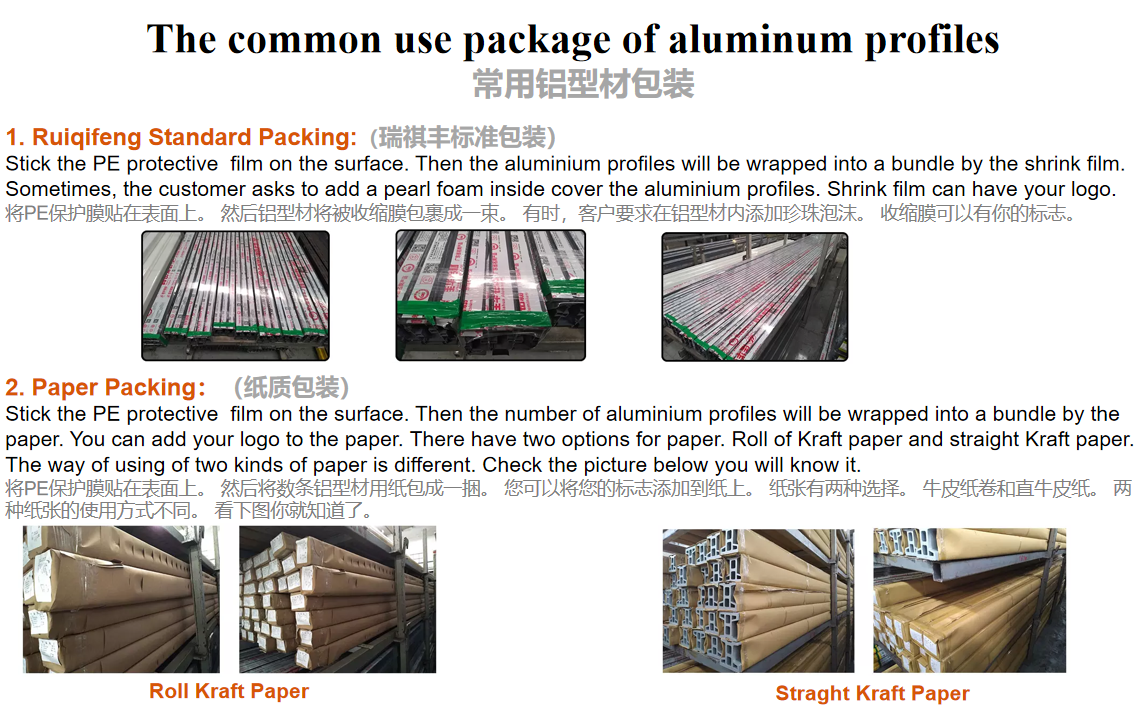

China OEM China New Enery Vehicles Battery Tray of Alunimum Extrusion

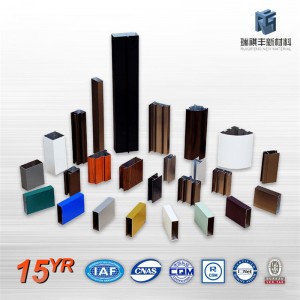

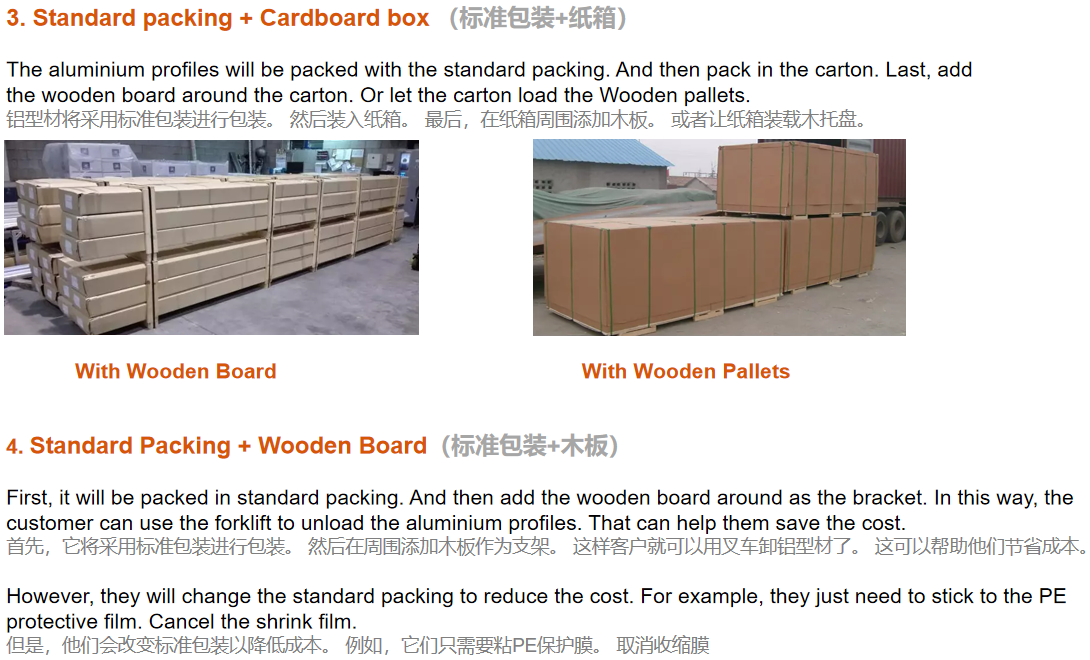

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for China OEM China New Enery Vehicles Battery Tray of Alunimum Extrusion, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

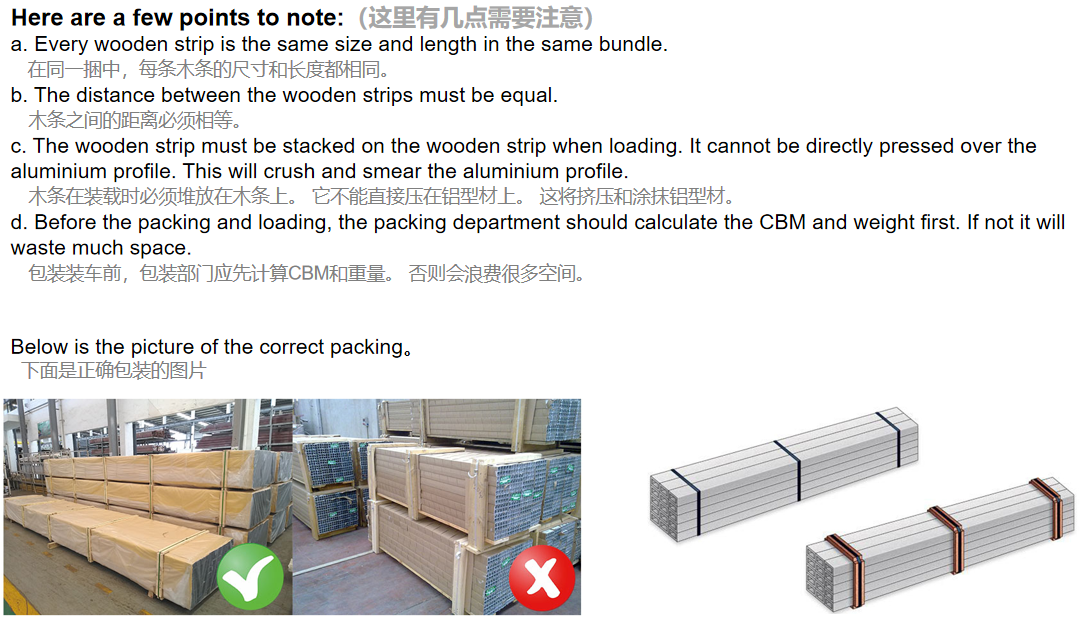

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for Aluminum Enclosure Parts for Electric Car, China Vehicle Battery Tray, Welcome any of your inquiries and concerns for our products and solutions. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you personally!

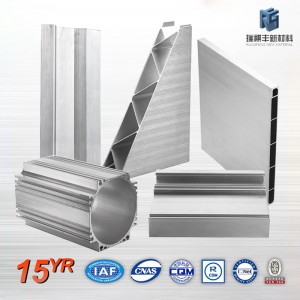

Product Process

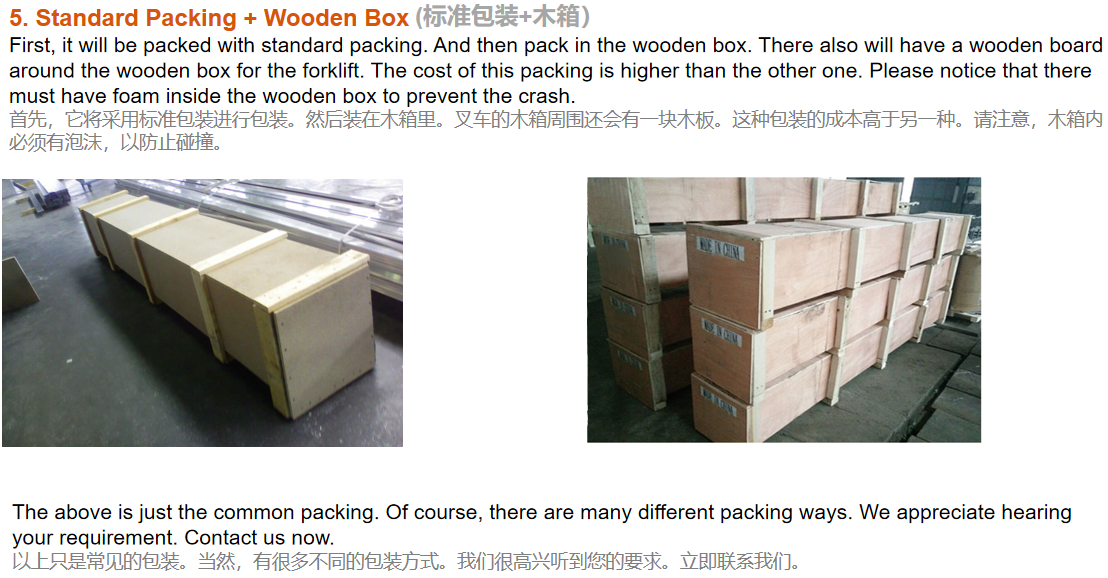

The IGBT heat sink is adopted the friction welding process, the two pieces of aluminum heat sink friction welding together, so as to achieve the IGBT heat sink need cross section, Finally, the integrated appearance structure and uniform heat dissipation performance are formed after CNC processing, the friction welding process can reduce the cost of the mould, cycle time is long, high stability. Lori has developed a variety of standard aluminum heat sink materials and continuously enhanced the standard materials database to provide customers with more joint solutions to choose from. The IGBT heat sink processing process is as follows

IGBT heat sink with heat pipe

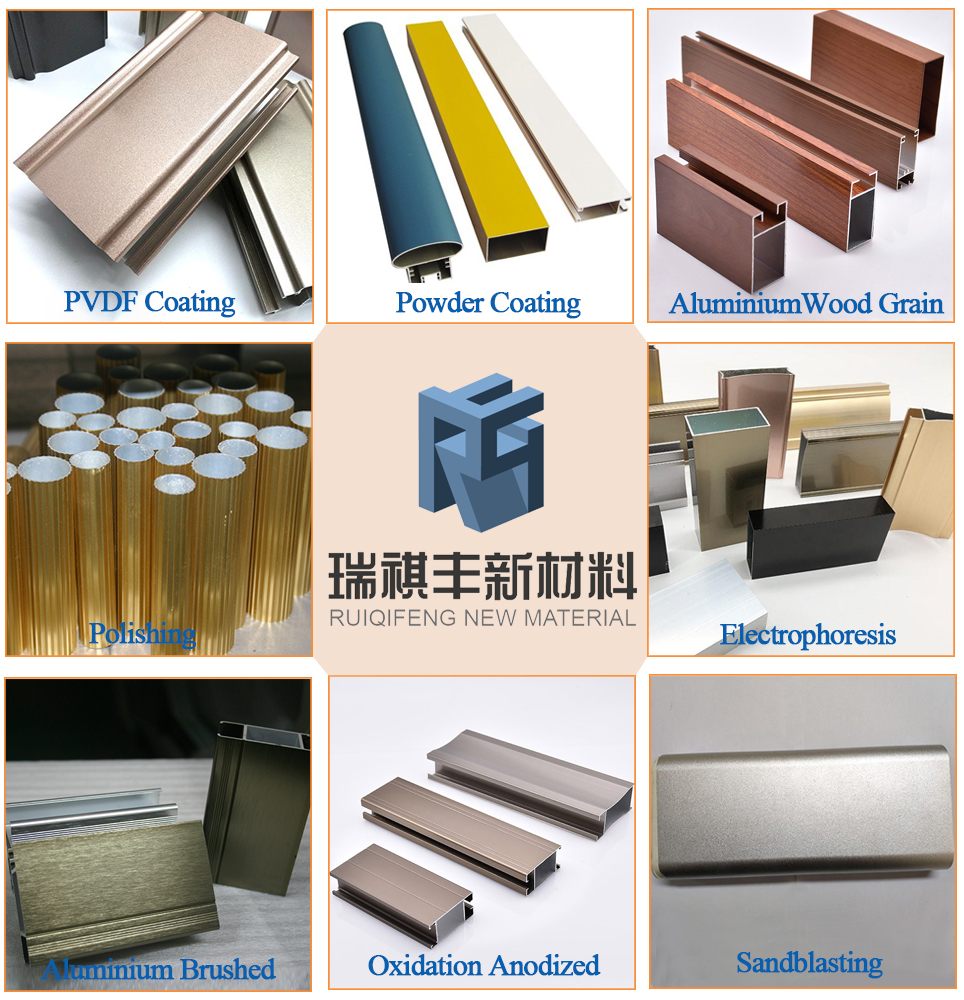

Product Details

This IGBT heat sink with heat pipe mainly included heat sink fin, heat pipe and base, wherein the base is provided with a number of mutually parallel grooves, the grooves are then soldered with solder to the evaporating section of the heat pipe

In the existing IGBT heat sink with heat pipe technology, the evaporating section of the heat pipe is buried in the base groove, which does not directly fit with the base of IGBT. During the IGBT working process, the heat on the surface of IGBT is firstly dissipated through the base, and the heat then transferred to the heat pipe and heat sink fin. Finally, the heat is transferred to the air by convection through the heat sink fins.

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for China OEM China New Enery Vehicles Battery Tray of Alunimum Extrusion, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

China OEM China Vehicle Battery Tray, Aluminum Enclosure Parts for Electric Car, Welcome any of your inquiries and concerns for our products and solutions. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you personally!

Guangxi Ruiqifeng New Material Co., Ltd.

Add: Pinggou Industrial Zone.Baise, Guangxi, China.

Tel: 86-776-5608888

Fax: 86-776-5608666 P.C.: 531499

Sales Center(Nanning)

Add: 1709, 21 Pingle Avenue, Liangqing District, Nanning, Guangxi

Mob: 0086-13556890771

E-mial: info@aluminum-artist.com

www.aluminum-artist.com (English) www.pgjf.com(Chinese)

As we all know, the economy is not very good this year, and raw materials are rising rapidly, so many companies will face the pressure of cost. However, we are in the resource place of bauxite, and we get the high quality liquid aluminum from the CHALCO, besides, we have the melting&casting workshop, mold manufacturing center, extrusion factory, and deep processing plant. All of these favorable factors mean we could provide you with more competitive prices, one-stop service, and guaranteed quality.

If not sure which item is right for you? please don’t hesitate to contact Ruiqifeng Technical, or directly call us at +86 13556890771, or request an estimate via Email (info@aluminum-artist.com).