Factory Selling High Power LED Lamp Heat Sinks Manufacturer Custom Die Casting Aluminum Products for LED Downlight 100W

Factory Selling High Power LED Lamp Heat Sinks Manufacturer Custom Die Casting Aluminum Products for LED Downlight 100W

Our organization has been focusing on brand strategy. Customers’ gratification is our greatest advertising. We also source OEM provider for Factory Selling High Power LED Lamp Heat Sinks Manufacturer Custom Die Casting Aluminum Products for LED Downlight 100W, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

Our organization has been focusing on brand strategy. Customers’ gratification is our greatest advertising. We also source OEM provider for China Heatsink Custom and LED Heatsink OEM ODM, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

| Place of Origin: | Guangxi | OEM: | Yes |

| Process: | Aluminum extrusion + Friction Welding | Temper: | T3-T8 |

| Material: | Aluminium Profile | Shape: | Square |

| Packing: | Standing Export Packing | Brand Name: | Ruiqifeng |

| Application: | IGBT | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | RQF003 | Tolerance: | 0.01 mm |

| Finish: | Clean+Anodized | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | 400*300*100 mm |

Product Details

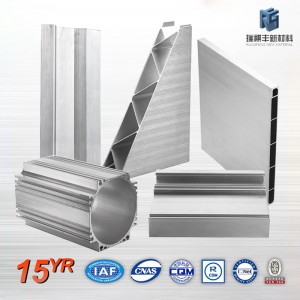

Ruiqifeng relying on long-term accumulated technical experience and production process sets aluminum alloy profiles with good thermal conductivity and other characteristics and develops a customized aluminum extruded heat sink that can meet customers’ requirements of product differentiation, specialization and personalization. The finished extruded heat sinks surface is anodized to improve the corrosion resistance, wear-resistance and appearance of aluminum. At present, the commonly used types of extruded aluminum heat sink in China are electronic heat sink, computer heat sink, sunflower heat sink, power semiconductor heatsink and so on. Because of their superior performance, extruded aluminum heat sinks are widely used in machinery, automobile, wind power, construction machinery, air compressor, railway locomotive, household appliances and other industries.

Product Features

This black anodized aluminum extruded heat sink is 260*125*50 mm, and we can provide some standard differernt sizes and shapes extruded heat sink for customer, There are 30,000+ sets standard molds in our stock for your option, saving your R&D cost. Also we can provide custom extruded heat sink design and manufacturing. We have more than 10 years professional manufacturing experience, more than 20 times aspect ratio heatsink can be extruded by 800 tons–5000 tons extruding machine by most advanced technology. Ultra wide extruded heatsink can be made by our unique friction welding technology. The production process for the extruded heat sinks are profiles extruding, cutting, CNC Machining(milling, drilling,tapping), deburring, cleaning, inspecting, packing. Surface Treatment included degreasing,(black) anodizing.

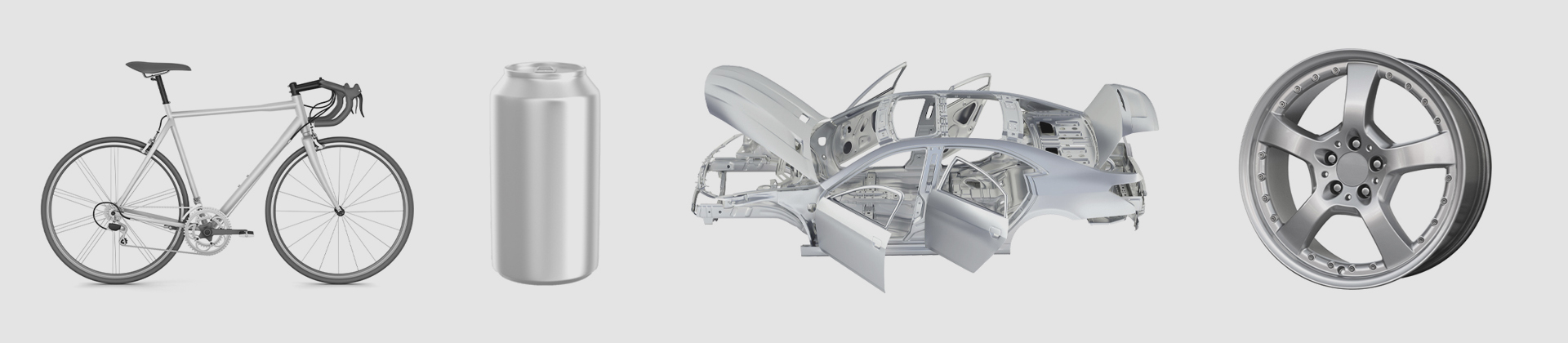

Product Application

Applied to Communication, UPS, inverter, controller, wind power converter, SVG telecommunication, LED Lighting, Power Supply Equipment, Electronic Industry,Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems,etc.Our organization has been focusing on brand strategy. Customers’ gratification is our greatest advertising. We also source OEM provider for Factory Selling High Power LED Lamp Heat Sinks Manufacturer Custom Die Casting Aluminum Products for LED Downlight 100W, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

Factory Selling China Heatsink Custom and LED Heatsink OEM ODM, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

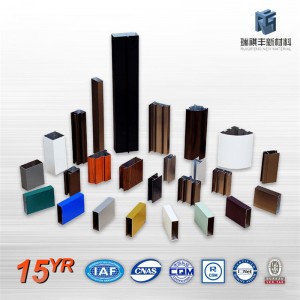

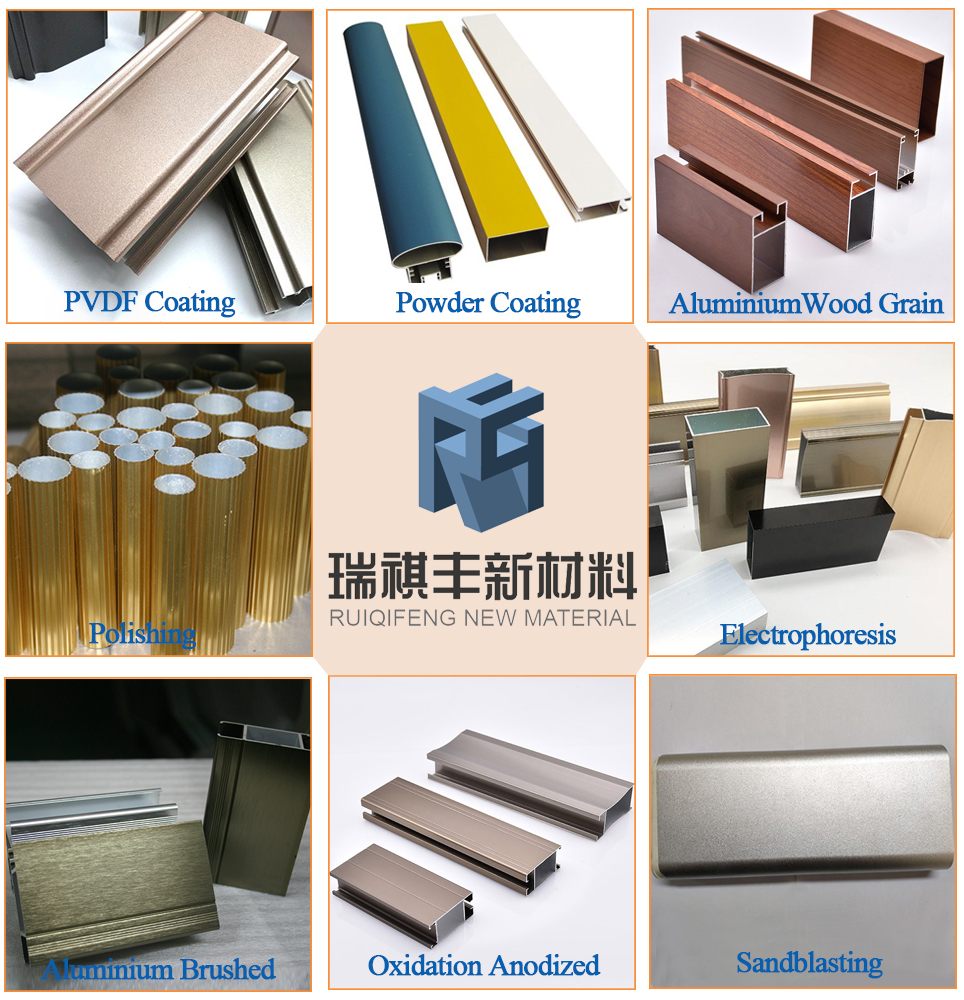

The common use package of aluminum profiles

1. Ruiqifeng Standard Packing:

Stick the PE protective film on the surface. Then the aluminium profiles will be wrapped into a bundle by the shrink film. Sometimes, the customer asks to add a pearl foam inside cover the aluminium profiles. Shrink film can have your logo.

2. Paper Packing:

Stick the PE protective film on the surface. Then the number of aluminium profiles will be wrapped into a bundle by the paper. You can add your logo to the paper. There have two options for paper. Roll of Kraft paper and straight Kraft paper. The way of using of two kinds of paper is different. Check the picture below you will know it.

3. Standard packing + Cardboard box

The aluminium profiles will be packed with the standard packing. And then pack in the carton. Last, add the wooden board around the carton. Or let the carton load the Wooden pallets.

4. Standard Packing + Wooden Board

First, it will be packed in standard packing. And then add the wooden board around as the bracket. In this way, the customer can use the forklift to unload the aluminium profiles. That can help them save the cost.

However, they will change the standard packing to reduce the cost. For example, they just need to stick to the PE protective film. Cancel the shrink film.

Here are a few points to note:

a. Every wooden strip is the same size and length in the same bundle.

b. The distance between the wooden strips must be equal.

c. The wooden strip must be stacked on the wooden strip when loading. It cannot be directly pressed over the aluminium profile. This will crush and smear the aluminium profile.

d. Before the packing and loading, the packing department should calculate the CBM and weight first. If not it will waste much space.

Below is the picture of the correct packing。

5. Standard Packing + Wooden Box

First, it will be packed with standard packing. And then pack in the wooden box. There also will have a wooden board around the wooden box for the forklift. The cost of this packing is higher than the other one. Please notice that there must have foam inside the wooden box to prevent the crash.

The above is just the common packing. Of course, there are many different packing ways. We appreciate hearing your requirement. Contact us now.

Loading & Shipment

As we all know, the economy is not very good this year, and raw materials are rising rapidly, so many companies will face the pressure of cost. However, we are in the resource place of bauxite, and we get the high quality liquid aluminum from the CHALCO, besides, we have the melting&casting workshop, mold manufacturing center, extrusion factory, and deep processing plant. All of these favorable factors mean we could provide you with more competitive prices, one-stop service, and guaranteed quality.

If not sure which item is right for you? please don’t hesitate to contact Ruiqifeng Technical, or directly call us at +86 13556890771, or request an estimate via Email (info@aluminum-artist.com).