Fixed Competitive Price 22 Gauge Aluminum Aheet Thickness in High Strength 5083 4mm Aluminium Sheet for Die Manufacturing

Fixed Competitive Price 22 Gauge Aluminum Aheet Thickness in High Strength 5083 4mm Aluminium Sheet for Die Manufacturing

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Fixed Competitive Price 22 Gauge Aluminum Aheet Thickness in High Strength 5083 4mm Aluminium Sheet for Die Manufacturing, Our products and solutions delight in fantastic popularity among the our buyers. We welcome prospects, company associations and close friends from all areas of your world to get in touch with us and seek out cooperation for mutual gains.

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for China Aluminum Sheet and Aluminium Sheet, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

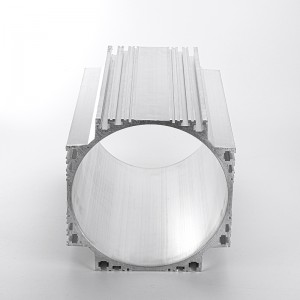

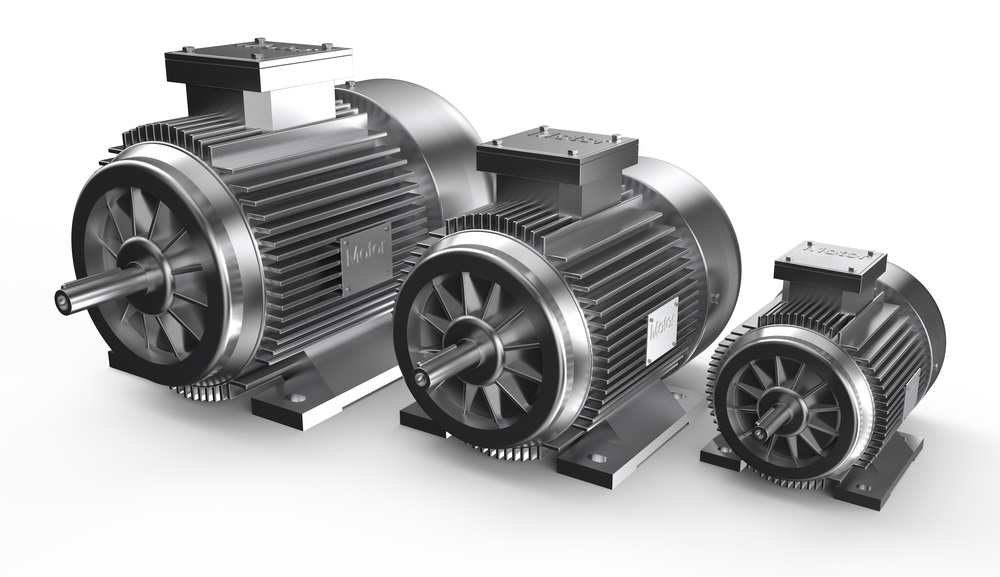

The aluminum extrusion motor body formed by hot extrusion has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, no cutting in the inner chamber, etc. Because of the poor concentricity between the shell and the end cover in the traditional processing of aluminum profile of motor shell, the motor running noise of aluminum alloy shell is large. According to the processing method of the aluminum profile of the motor shell, a processing tool for the aluminum extrusion motor bodyis designed. The aluminum extrusion motor body can be processed by two end stops of the aluminum extrusion motor body after one clamping. The concentricity of the inner hole of the aluminum extrusion motor bodyis ≤ 0.02mm, which can improve the production efficiency by more than one time, and solve the problem of large noise of the aluminum profile motor of the motor shell.

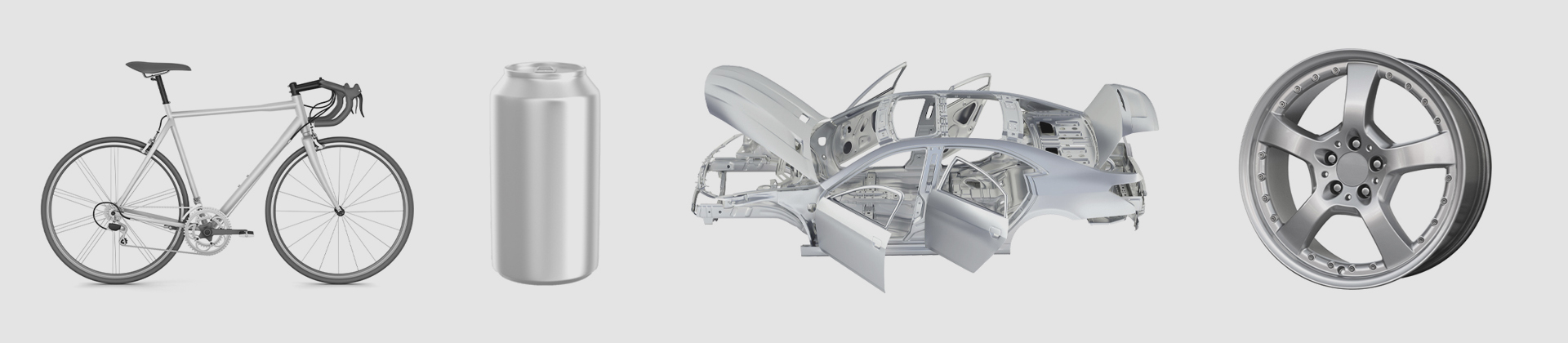

Application

The extruded aluminum motor shell housing produced by Ruiqifeng are also used for: micro motor case, environmental protection air conditioning motor case, cooling fan motor case, water-cooling air conditioning motor case, air compressor motor case, negative pressure fan, motor case, electric vehicle motor case, tricycle motor case, servo motor special case, injection molding machine motor, cooling tower motor, cylinder, axial flow wind Machine motor, electric tool motor, reducer motor, etc..

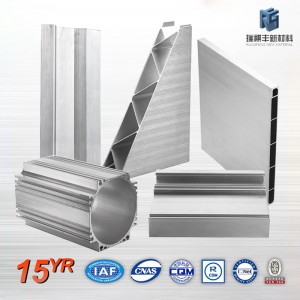

| Item | Aluminum profiles for Motor Enclosure |

| Material & Temper: | 6000Series, 6063/6061/6005/6060 T3-T8 |

| Size/thickness | General thickness from 0.8-5mm,length from 3m-6m or customized sizes |

| Production capacity: | 100,000 tons per year |

| Processing Service: | Bending, Welding, Punching, Cutting |

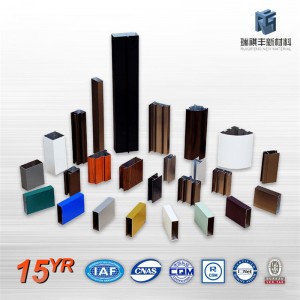

| Color: | Customized Color |

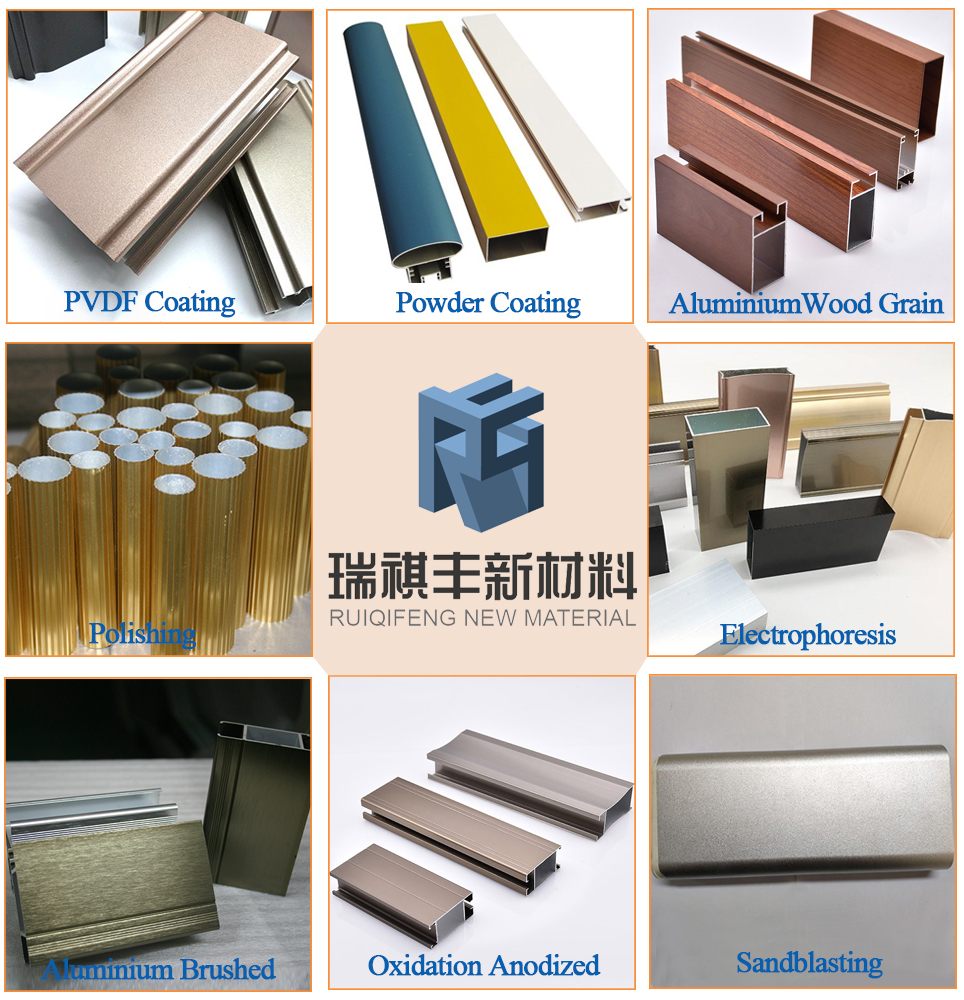

| Surface Finish: | Powder Coating, Anodized, Wooden grain, Polishing, Eletrophoresis |

| Certification: | ISO9001:2008,ISO14001:2004 |

| Packing | packed with poly protective film, and wrap to be bundles by waterprof craft paper |

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Fixed Competitive Price 22 Gauge Aluminum Aheet Thickness in High Strength 5083 4mm Aluminium Sheet for Die Manufacturing, Our products and solutions delight in fantastic popularity among the our buyers. We welcome prospects, company associations and close friends from all areas of your world to get in touch with us and seek out cooperation for mutual gains.

Fixed Competitive Price China Aluminum Sheet and Aluminium Sheet, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The common use package of aluminum profiles

1. Ruiqifeng Standard Packing:

Stick the PE protective film on the surface. Then the aluminium profiles will be wrapped into a bundle by the shrink film. Sometimes, the customer asks to add a pearl foam inside cover the aluminium profiles. Shrink film can have your logo.

2. Paper Packing:

Stick the PE protective film on the surface. Then the number of aluminium profiles will be wrapped into a bundle by the paper. You can add your logo to the paper. There have two options for paper. Roll of Kraft paper and straight Kraft paper. The way of using of two kinds of paper is different. Check the picture below you will know it.

3. Standard packing + Cardboard box

The aluminium profiles will be packed with the standard packing. And then pack in the carton. Last, add the wooden board around the carton. Or let the carton load the Wooden pallets.

4. Standard Packing + Wooden Board

First, it will be packed in standard packing. And then add the wooden board around as the bracket. In this way, the customer can use the forklift to unload the aluminium profiles. That can help them save the cost.

However, they will change the standard packing to reduce the cost. For example, they just need to stick to the PE protective film. Cancel the shrink film.

Here are a few points to note:

a. Every wooden strip is the same size and length in the same bundle.

b. The distance between the wooden strips must be equal.

c. The wooden strip must be stacked on the wooden strip when loading. It cannot be directly pressed over the aluminium profile. This will crush and smear the aluminium profile.

d. Before the packing and loading, the packing department should calculate the CBM and weight first. If not it will waste much space.

Below is the picture of the correct packing。

5. Standard Packing + Wooden Box

First, it will be packed with standard packing. And then pack in the wooden box. There also will have a wooden board around the wooden box for the forklift. The cost of this packing is higher than the other one. Please notice that there must have foam inside the wooden box to prevent the crash.

The above is just the common packing. Of course, there are many different packing ways. We appreciate hearing your requirement. Contact us now.

Loading & Shipment

As we all know, the economy is not very good this year, and raw materials are rising rapidly, so many companies will face the pressure of cost. However, we are in the resource place of bauxite, and we get the high quality liquid aluminum from the CHALCO, besides, we have the melting&casting workshop, mold manufacturing center, extrusion factory, and deep processing plant. All of these favorable factors mean we could provide you with more competitive prices, one-stop service, and guaranteed quality.

If not sure which item is right for you? please don’t hesitate to contact Ruiqifeng Technical, or directly call us at +86 13556890771, or request an estimate via Email (info@aluminum-artist.com).