Good Quality Aluminum Profiles - Extruded Aluminium Motor Enclosure – Ruiqifeng

Good Quality Aluminum Profiles - Extruded Aluminium Motor Enclosure – Ruiqifeng

Good Quality Aluminum Profiles - Extruded Aluminium Motor Enclosure – Ruiqifeng Detail:

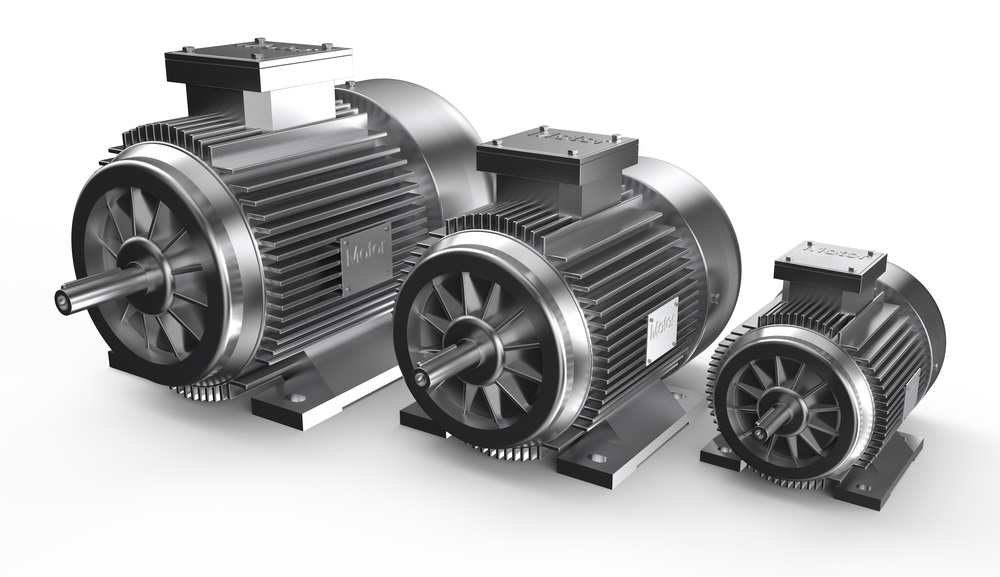

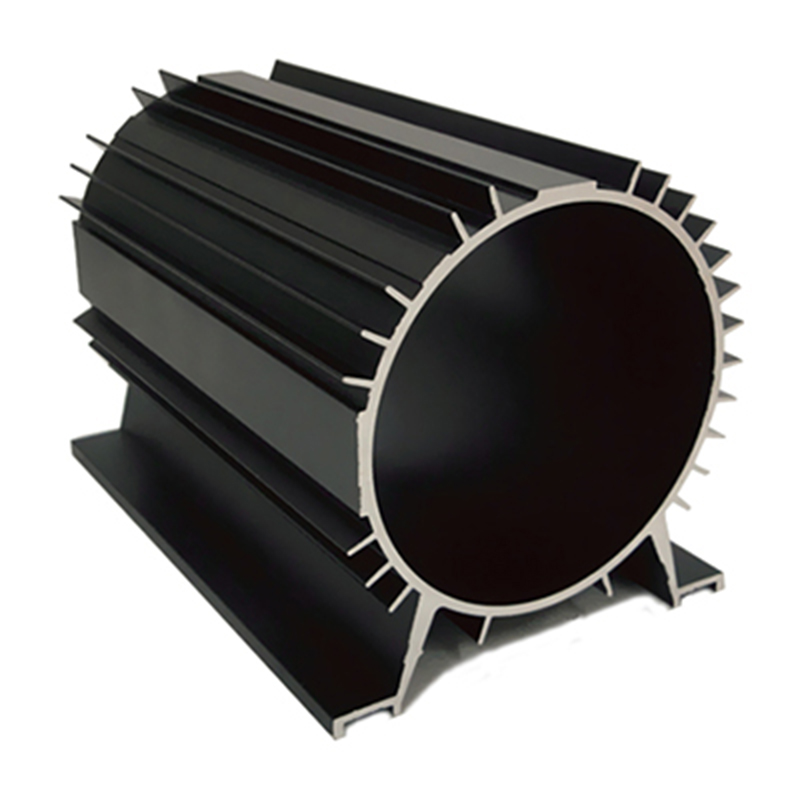

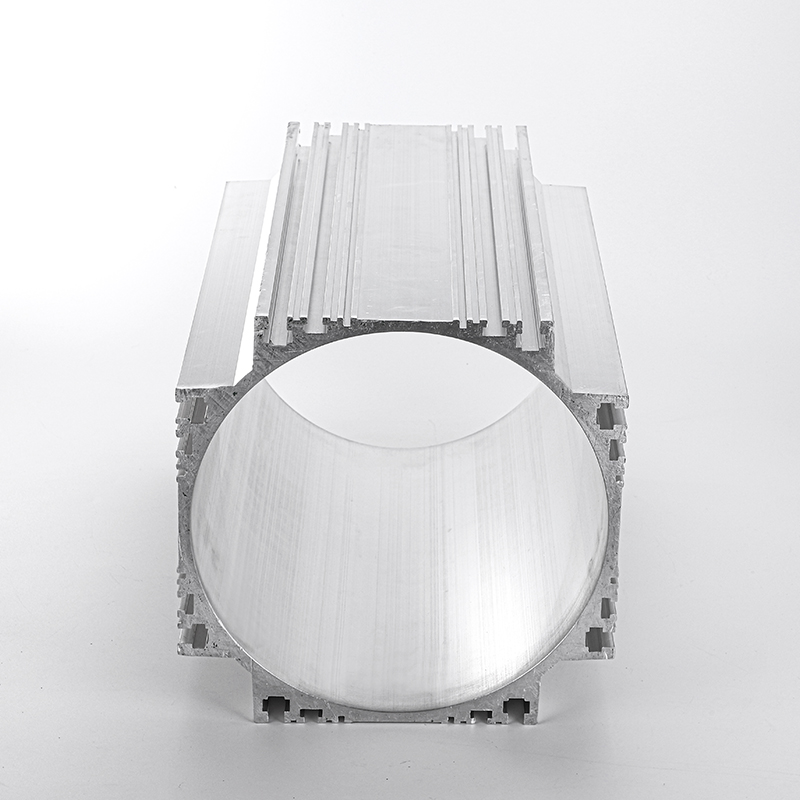

The aluminum extrusion motor body formed by hot extrusion has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, no cutting in the inner chamber, etc. Because of the poor concentricity between the shell and the end cover in the traditional processing of aluminum profile of motor shell, the motor running noise of aluminum alloy shell is large. According to the processing method of the aluminum profile of the motor shell, a processing tool for the aluminum extrusion motor bodyis designed. The aluminum extrusion motor body can be processed by two end stops of the aluminum extrusion motor body after one clamping. The concentricity of the inner hole of the aluminum extrusion motor bodyis ≤ 0.02mm, which can improve the production efficiency by more than one time, and solve the problem of large noise of the aluminum profile motor of the motor shell.

Application

The extruded aluminum motor shell housing produced by Ruiqifeng are also used for: micro motor case, environmental protection air conditioning motor case, cooling fan motor case, water-cooling air conditioning motor case, air compressor motor case, negative pressure fan, motor case, electric vehicle motor case, tricycle motor case, servo motor special case, injection molding machine motor, cooling tower motor, cylinder, axial flow wind Machine motor, electric tool motor, reducer motor, etc..

| Item | Aluminum profiles for Motor Enclosure |

| Material & Temper: | 6000Series, 6063/6061/6005/6060 T3-T8 |

| Size/thickness | General thickness from 0.8-5mm,length from 3m-6m or customized sizes |

| Production capacity: | 100,000 tons per year |

| Processing Service: | Bending, Welding, Punching, Cutting |

| Color: | Customized Color |

| Surface Finish: | Powder Coating, Anodized, Wooden grain, Polishing, Eletrophoresis |

| Certification: | ISO9001:2008,ISO14001:2004 |

| Packing | packed with poly protective film, and wrap to be bundles by waterprof craft paper |

Product detail pictures:

Related Product Guide:

Ruiqifeng New Materials Co., Ltd. is a well-known profile aluminum supplier, specializing in profile aluminium extrusion production with nearly 20 years of experience. Our factory is headquartered in Pingguo, Guangxi, with a superior geographical location and rich aluminum ore resources. This advantageous position enables us to offer high quality profile aluminium at competitive raw material prices. Equipped with advanced production technology, our company is committed to becoming a leading exporter of first-class profile aluminium. As a comprehensive service provider, we provide a complete solution, including design, mold making, production, transportation and after-sales support. Our experienced sales team will work hard to meet your requirements throughout the entire process to ensure you receive a satisfactory solution. We offer a variety of aluminium profiles, including architectural profiles, industrial aluminium profiles, decorative profiles, and more. Customization is at the core of our services, as we aim to meet the unique needs of different projects based on our clients' specific requirements. Our products are of excellent quality, reliable performance and beautiful design. They undergo strict quality control and testing procedures to ensure compliance with industry standards and exceeding customer expectations. Richifeng is driven by the pursuit of excellence and innovation. We continuously invest in research and development to enhance our product processes and technologies to adapt to the changing needs of the market. Over the years, we have established mutually beneficial cooperative relationships with many well-known companies, providing them with high-quality aluminum frame products and winning a good reputation and trust. Integrity, quality and innovation are the guiding principles of our operations. We strive to grow and develop together with our esteemed customers. Through our dedicated efforts and collaborative spirit, we aim to provide our customers with quality aluminum framing products that contribute to the success of their projects. If you have any interest in our products or have any questions, please feel free to contact us. We eagerly look forward to the opportunity to cooperate with you and create a better future together! Good Quality Aluminum Profiles - Extruded Aluminium Motor Enclosure – Ruiqifeng , The product will supply to all over the world, such as: Turin, Albania, Barbados, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!