Hot-selling Aluminum Extrusion Profile - New Enery Vehicles Battery Tray of Alunimum Extrusion – Ruiqifeng

Hot-selling Aluminum Extrusion Profile - New Enery Vehicles Battery Tray of Alunimum Extrusion – Ruiqifeng

Hot-selling Aluminum Extrusion Profile - New Enery Vehicles Battery Tray of Alunimum Extrusion – Ruiqifeng Detail:

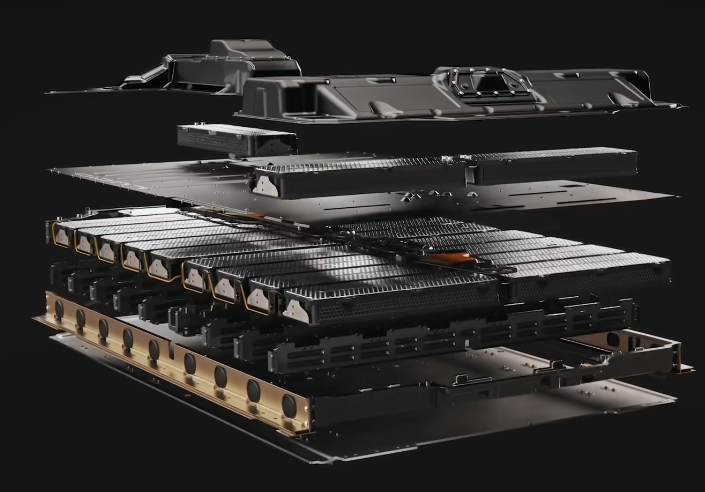

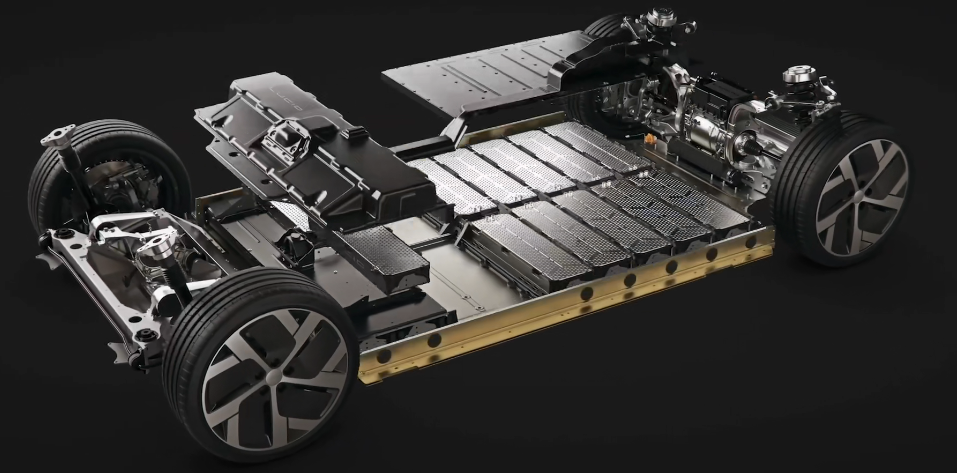

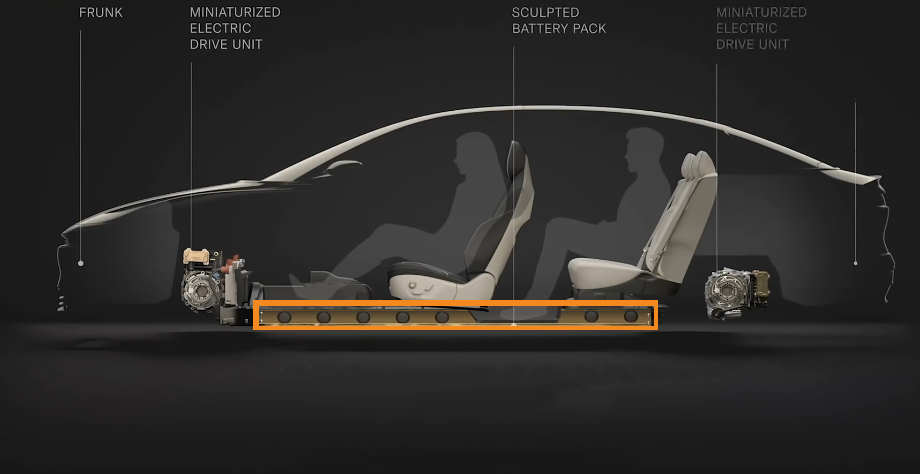

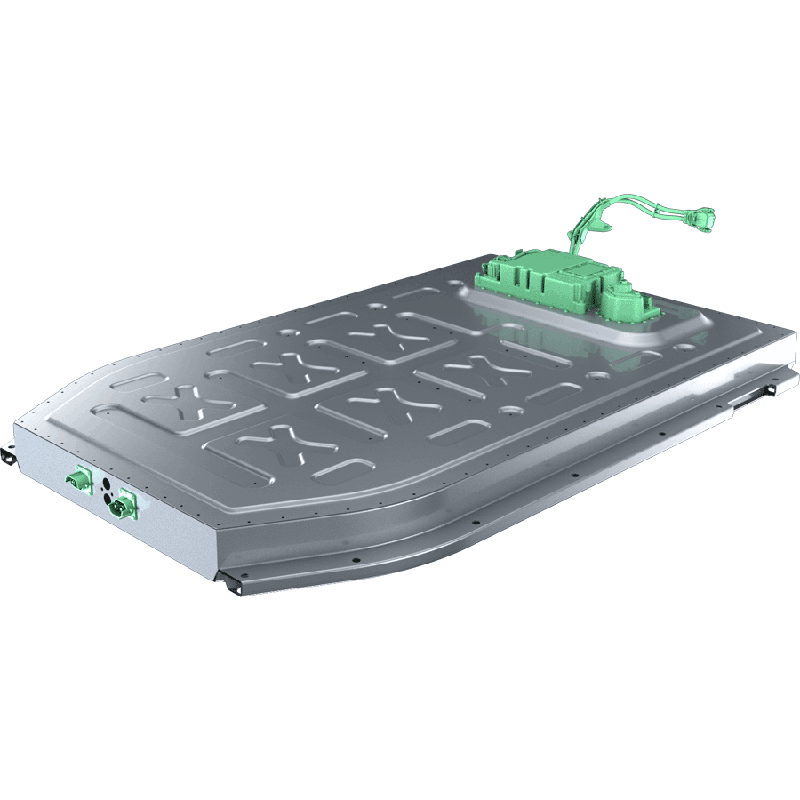

Electric Vehicle Reinforced Aluminum Battery Housing Solution

The advanced reinforced aluminum sheet design is aimed at promoting the aluminum housing for mass production of electric vehicles worldwide, and the extruded aluminum solution minimizes the energy consumption compared to the traditional EV battery housing made of steel or extruded aluminum. Weight, lower cost, and higher energy density of battery packs.

NEV Battery Tray

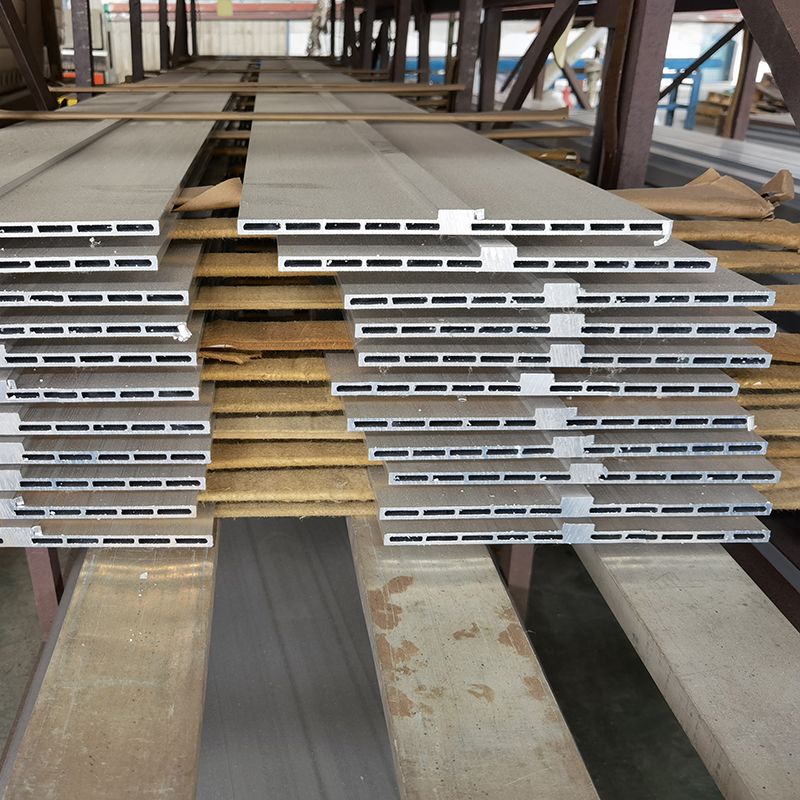

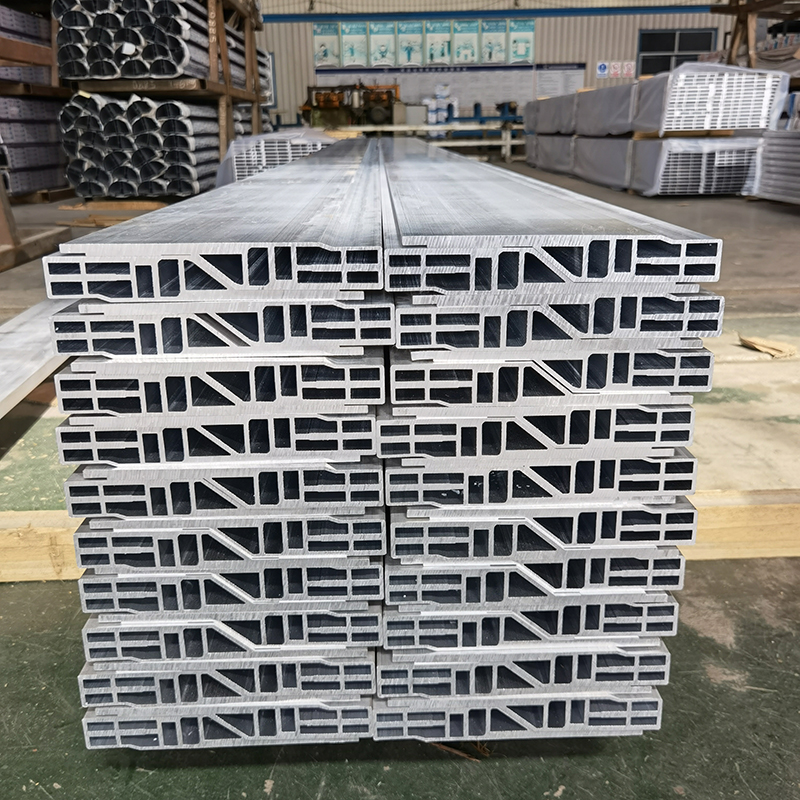

As the main bear part of power battery, Ruiqifeng has manufacturing the battery tray’s machines, such as extrusion machine, bending machine, friction stir welding, arc welding, gantry machining-center etc, and can also manufacturing 20,000PCS a month.

Friction Stir Welded aluminium

R & D of new materials and application of new technologies help automobile manufacturers lighten the weight of vehicles and meet the requirements of energy saving and emission reduction.

Our advantages

1. Technician team: over 30 years of experience in Aluminium extrusion for industrial application.

2. Rich source of Aluminium ingot locally.

3. Export staff embodied with fluent English communication skills, good knowledge in aluminium extrusion industries, and exports. Stable and reliable to help to sort out all problems.

4. Wide range of Aluminium alloy materials available.

5. Undertake any quality problems unconditionally.

FAQ

Q1: Any MOQ required?

A: We accept any quantity you may need. But there will be set-up charge for small order.

Q2: What is the lead time for tooling and off-tool samples?

A: For small tooling (External size less than 229mm), it takes about 10-15 days for tooling and about 5 days for off-tool samples preparing.

Q3: How about the payment terms?

A: For tooling, 100% prepayment by TT bank; for bulk production, 30% prepayment by TT bank, and balance against delivery.

Q4: Will you send videos or pictures in the processing?

A: Yes, we will keep you updated about the status here by sending videos or pictures.

You can start with a small trial. Just send me your drawings!

Look forward to hearing from you.

Product detail pictures:

Related Product Guide:

Ruiqifeng New Materials Co., Ltd. is a factory specializing in aluminum profile extrusion production, with nearly 20 years of production experience. We are committed to providing customers with high-quality aluminum curtain wall solutions. Our factory is fully equipped and adopts advanced technology and processes to ensure the excellent quality and competitiveness of our products. As a company that provides one-stop services, Ruiqifeng can provide full follow-up from design and mold opening to production, shipment and after-sales. We have an experienced sales team to provide customers with professional guidance and services. Whether you are an individual consumer, a real estate developer or a construction company, we have the ability to customize aluminum profile curtain walls according to your specific needs. Our factory is located in Pingguo, Guangxi, an area with abundant aluminum ore resources, allowing us to produce aluminum profiles with high quality and competitive raw material prices. We pay attention to environmental protection and strictly abide by relevant regulations and standards to ensure the sustainable development of the production process. Our products undergo rigorous testing and quality control to meet the high standards and expectations of the industry and customers. Ruiqifeng has extensive experience in the production of aluminum profile curtain walls and has cooperative relationships with companies such as YKK, Fangda Group, Top Tier Facade, etc. We continue to innovate and improve to provide our customers with aluminum curtain wall solutions that are best suited for their projects. Ruiqifeng is your trustworthy partner. Based on the principles of integrity, quality and innovation, we are committed to developing together with our customers. Whether you need personalized aluminum profile curtain walls or other customized extrusion products, we will wholeheartedly provide you with a satisfactory solution. If you are interested in our products or have any questions, please feel free to contact us. We look forward to the opportunity to work with you! Hot-selling Aluminum Extrusion Profile - New Enery Vehicles Battery Tray of Alunimum Extrusion – Ruiqifeng , The product will supply to all over the world, such as: Canada, Sheffield, kazakhstan, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.