What You Should Know About Aluminium Extrusion?

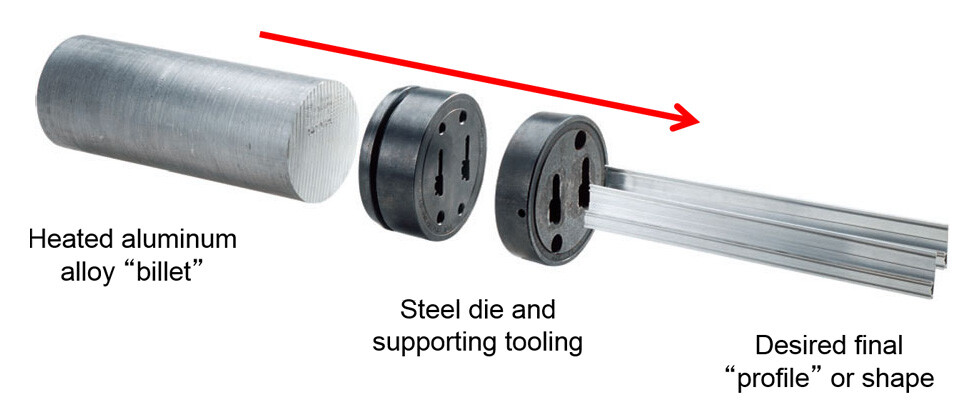

Aluminium extrusion is a versatile and widely used process in the manufacturing industry. The process of aluminium extrusion involves creating complex cross-sectional profiles by pushing aluminium billets or ingots through a die with hydraulic pressure, resulting in long, continuous shapes with consistent cross-sections.

For people who don’t understand the concept of an extrusion, think back to when you were a child and played with play-dough. Remember putting the play-dough in the hopper and then when you pushed the handle down a special shape came out? That is an extrusion.

Here are several key points that anyone working with aluminium extrusion should know.

Design Flexibility:

One of the significant advantages of aluminium extrusion is its design flexibility. With the ability to create complex cross-sectional profiles, aluminium extrusions offer a wide range of possibilities for product design. This flexibility is particularly valuable for industries such as construction, automotive, aerospace, and consumer goods, where lightweight, durable, and aesthetically pleasing components are essential.

Alloys and Properties:

Aluminium extrusion can be performed with various aluminium alloys, each offering specific properties suited for different applications. The choice of alloy can affect the extrusion process, as well as the properties of the final product, such as strength, corrosion resistance, and conductivity. Understanding the different alloy options and their performance characteristics is crucial in selecting the ideal material for a specific application.

Surface Finishing:

Aluminium extrusions can be finished in a variety of ways to enhance their appearance and performance. Processes such as anodizing, painting, powder coating, and mechanical finishing can provide improved corrosion resistance, durability, and aesthetic appeal. It is essential to consider the intended end-use and environmental conditions when selecting the appropriate surface finishing technique.

Tolerances and Quality Control:

Maintaining tight tolerances and ensuring consistent quality are crucial aspects of the aluminium extrusion process. Understanding the capabilities of the extrusion equipment and the properties of the chosen alloys is essential for achieving the desired precision and product quality. Quality control measures such as dimensional inspections, material testing, and process monitoring are integral to ensuring that extruded components meet the required specifications.

Sustainability:

Aluminium is a highly sustainable material, and aluminium extrusion further enhances its eco-friendly credentials. The extrusion process minimizes material waste, as it allows for the precise shaping of profiles with minimal scrap. Additionally, aluminium is fully recyclable, making extruded products an environmentally responsible choice for manufacturers and end-users alike.

Applications and Market Trends:

Aluminium extrusions find extensive use in various industries, including architecture, transportation, electronics, and renewable energy. The demand for lightweight, high-strength, and corrosion-resistant components continues to drive the growth of aluminium extrusion applications. Market trends such as the shift towards electric vehicles, sustainable construction practices, and the increasing use of aluminium in consumer electronics highlight the continued relevance of aluminium extrusion in modern manufacturing.

Understanding the intricacies of aluminium extrusion is vital for maximizing the potential of this versatile manufacturing process. As technology and design practices continue to evolve, the use of aluminium extrusions is expected to expand, providing new opportunities for manufacturers and designers to create innovative, sustainable solutions. Welcome any inquiries about aluminium extrusion with us.

Post time: Jan-11-2024