Application and development of aluminum alloy in ocean engineering

-Application of offshore helicopter platform

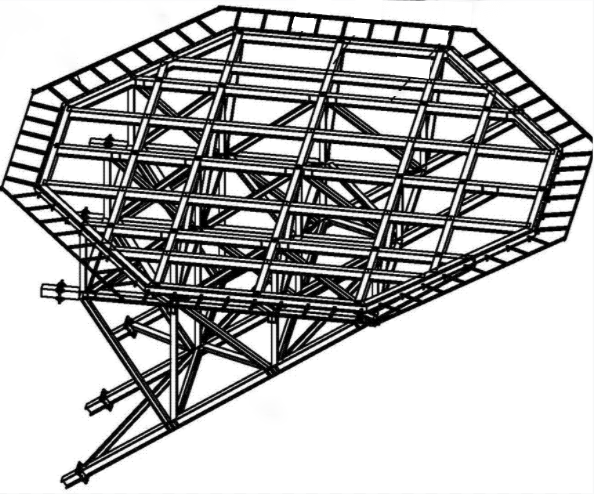

Offshore oil drilling platform uses steel as the main structural material, because of long-term exposure to the Marine environment, although steel has a high strength, it faced with a series of problems such as corrosion, short service life. Helideck is a very important part of the infrastructure of offshore oil and gas resources development. It is used for the take-off and landing of helicopters and is an important link to maintain contact with the land. Due to its large volume, it should also have the requirements of its weight, structural stiffness and other aspects. Aluminum helicopter deck module is widely used because of its light weight, good strength and stiffness.

The aluminum alloy helicopter platform comprises a bottom frame and a deck block fixed on the bottom frame made of aluminum alloy profiles spliced together. The section of profiles is similar to the word “工”, and a stiffened plate cavity is arranged between the upper and lower bottom plates. The mechanical principle and bending strength of aluminum alloy profiles are utilized to meet the performance requirements and reduce the dead weight. In addition, in the Marine environment, the aluminum alloy helicopter platform is easy to maintain, good corrosion resistance; Adopt profile splicing mode, avoid welding, no welding heat affected zone, can prolong service life, avoid failure.

-Application on LNG(liquefied natural gas) cargo ships

With the continuous development of offshore oil and gas resources, major natural gas supply areas and demand areas in the world are far away from each other, often separated by oceans. Therefore, ocean shipping is the main transportation of LIQUEFIED natural gas at present. In the design of LNG ship storage tank, the metal with good low temperature performance and certain strength and toughness is needed. The strength of aluminum alloy material at low temperature is higher than that at room temperature, and aluminum alloy is light in weight and corrosion resistant in Marine atmosphere, which is the ideal material for use at low temperature.

5083 aluminum alloy is also widely used in the manufacture of LNG ships and LNG storage tanks. Especially, Japan, the largest importer of LNG, built a series of LNG storage tanks and transport ships from the 1950s and 1960s, among which there’s LNG storage tank with main wall structure of all 5083 aluminum alloy. Most aluminum alloys are important materials for tank top structure because of their light weight and corrosion resistance. At present, there are only a few companies in the world that can produce low temperature aluminum material for LNG carrier storage tanks. 5083 aluminum alloy 160mm extra thick plate developed by Japan has good low temperature toughness and fatigue resistance.

-Application on Marine wharf

Marine dock equipment such as gangway, floating bridge and passageway is made of 6005A or 6060 aluminum alloy welded, floating dock is made of 5754 aluminum alloy welded watertight tank body, structure or floating dock do not need to be painted or chemical treatment.

-Aluminium alloy drill pipe

Aluminum alloy drill pipe has the properties of low density, light weight, high specific strength, small rotary torque required, strong impact resistance, good corrosion resistance, and small friction resistance between the hole wall. In the case of a certain drilling capacity, the application of aluminum alloy drill pipe can reach the well depth which steel drill pipe can not achieved. At present, aluminum alloy drill pipe has been successfully used in oil exploration. Since the 1960s, aluminum alloy drill pipe has been widely used in the Soviet Union. In the Soviet Union, aluminum alloy drill pipe has been used to drill 70% to 75% of the total footage. In the offshore drilling platform, combined with the advantages of aluminum alloy corrosion resistance, high performance aluminum alloy drill pipe has a great application prospect in the offshore engineering.

Post time: May-24-2022