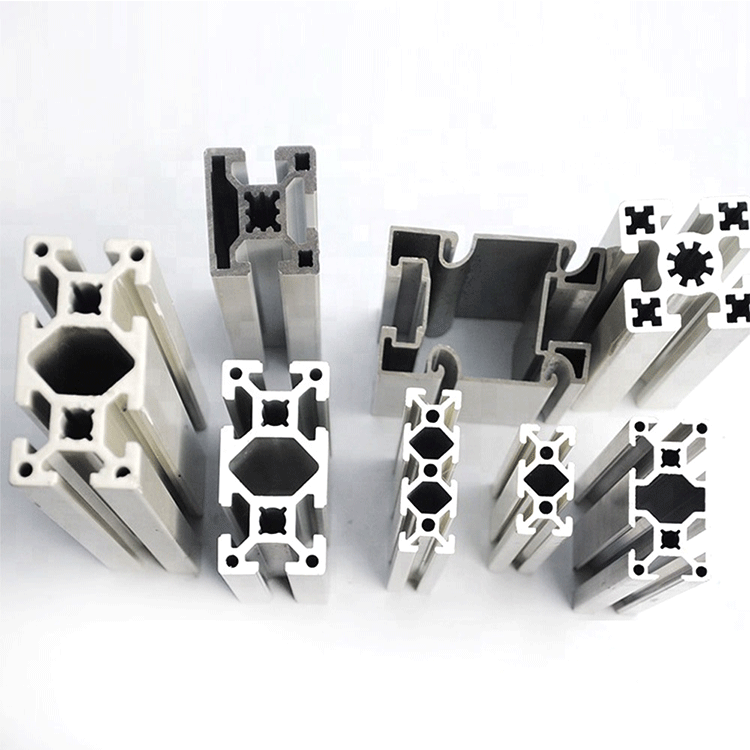

T-slot aluminum profiles are widely used in industrial manufacturing, mechanical equipment, and automation systems due to their high strength, lightweight properties, and versatility. Need a durable, high-performance custom T-slot aluminum profile for your next project? Our custom extrusion services offer unmatched flexibility and quality.

Design and Extrusion Process

T-slot aluminum profiles are made from aluminum alloys such as 6063-T5 or 6061-T6 through a hot extrusion process. During extrusion, aluminum billets are heated to 450-500°C and pushed through a mold to form specific cross-sections. Ruiqifeng Key characteristics include:

- High precision dimensional control (tolerance within ±0.1mm).

- Smooth surface finish for easy post-processing.

- A balance of strength and rigidity, making it suitable for load-bearing structures.

Surface Treatment

Industrial aluminum profiles undergo surface treatment to enhance corrosion resistance and aesthetics. Common surface treatments include:

- Anodizing (oxidation layer thickness of 5-25μm, improving wear resistance).

- Powder Coating (available in various colors).

- Electrophoretic Coating (enhancing surface hardness and weather resistance).

Applications of T-slot Aluminum Profiles

T-slot aluminum profiles are widely used in:

- Industrial Automation (such as assembly line frames).

- Mechanical Equipment (such as machine guards and testing devices).

- Electronic Equipment (such as cabinets and server racks).

- Construction Industry (such as curtain wall support structures).

Aluminum Profile Connection Methods

Aluminum profiles offer a variety of connection methods, typically using specialized accessories without the need for welding. This makes them environmentally friendly and easy to assemble, disassemble, transport, and relocate. In custom designs, aluminum profiles are extensively used.

Here are 20 common connection methods:

- Built-in Connector: Used for 90° connections between two profiles; hidden connection with high strength.

- Corner Brackets (90°, 45°, 135°): Used for external angle connections at 90°, 45°, and 135°; can secure panel attachments.

- Screw Connection: Used for 90° internal connections; easy to install and remove, commonly used in simple enclosures.

- L-shaped Slot Connector (90°): Used for 90° connections; easy to install and does not require additional machining.

- High-Strength Slot Connector (45°): Used for 45° slot connections; strong and commonly used in door frames.

- End Face Connector: Used for right-angle connections between two or three profiles; firm and aesthetically pleasing.

- 3D Connector (Right Angle): Used for right-angle connections among three profiles; quick and easy.

- 3D Connector (R Angle): Used for right-angle connections among three curved profiles; quick and easy.

- Elastic Clip: Used for 90° internal connections; easy to install and remove.

- End Connector: Used for 90° internal connections; concealed and high-strength.

- Straight Connector: Used for high-strength inline connections between two profiles.

- Anchor Connector: Used for profile connections with multiple angle options; concealed and convenient.

- Adjustable Hinge: Used for profile connections, adjustable between 30°-150°.

- Rotary Connection Plate: Used for various profile connections with multi-angle rotation.

- Connection Plate: Used for multiple profile connections; high-strength and requires no additional machining.

- Rotary Corner Bracket: Allows connection at any angle.

- Bolt Head Assembly: Inserts elastic nuts into one profile and a round post into another, secured with a bolt.

- Cross-Shaped External Connection Plate: Used for high-strength “+” structure connections.

- L-Type, T-Type External Connection Plate: Used for high-strength “L” or “T” structure connections.

- Y-Type External Connection Plate: Used for high-strength “-” structure connections.

These connection methods can be demonstrated through animated diagrams, making it easier for engineers to select the most suitable connection solutions during the design process.

Post time: Feb-28-2025