Do you know that aluminum extrusion is shaping the future of the industry?

In recent years, aluminum extrusions have become a versatile and cost-effective solution for a variety of industrial applications. Aluminum’s lightness and strength, combined with its excellent strength-to-weight ratio, make it an attractive choice for industries across the globe. In this article, we will explore the wide range of applications of aluminum extrusions in the industrial field.

Aerospace industry:

Aluminum extrusions have revolutionized the aerospace industry as they provide exceptional strength while significantly reducing the weight of aircraft. From fuselage frames to wing structures, aluminum extrusions are widely used for their ability to improve fuel efficiency, improve maneuverability and ultimately reduce operating costs.

Automobile industry:

Aluminum extrusions have become an important part of the automotive industry, especially in the manufacture of light vehicles. By using aluminum extrusions in chassis, body structure and interior components, automakers can achieve superior energy efficiency, improve overall performance and raise safety standards. Additionally, the recyclability of aluminum makes it an environmentally sustainable choice for the automotive industry.

Construction industry:

With their superior strength, durability and corrosion resistance, aluminum extrusions have become the first choice in the construction industry. From window frames and curtain walls to building facades, aluminum profiles provide excellent thermal performance and structural integrity. Their versatility and ease of fabrication also make them suitable for use in modular building systems, facilitating faster project completion.

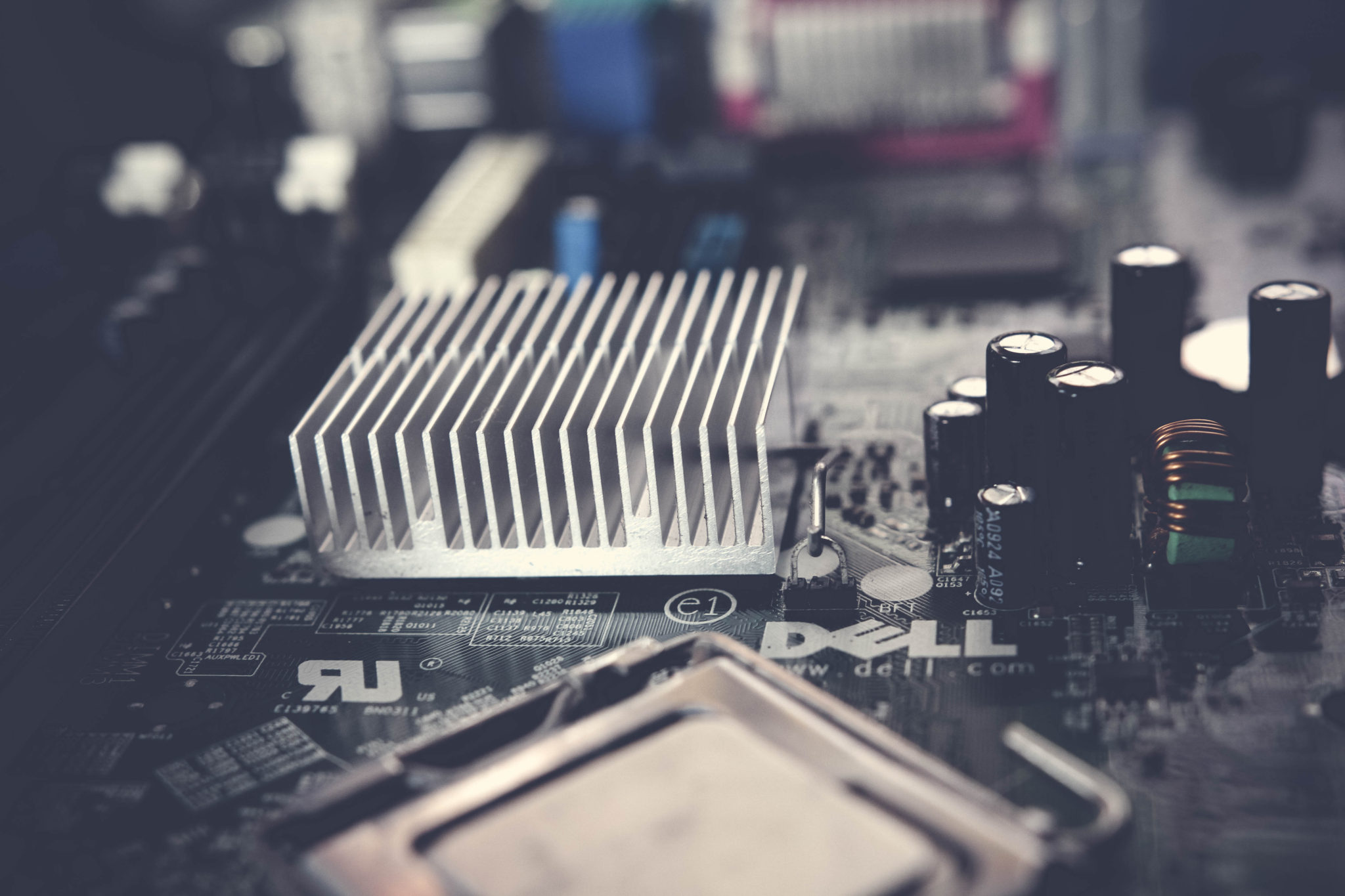

IT:

Aluminum profiles are widely used in the electronics industry, especially in the production of radiators. As the demand for advanced electronic devices continues to grow, heat dissipation becomes a key factor. The excellent thermal conductivity of aluminum profiles ensures effective thermal management, extending the life and performance of electronic components.

Furniture industry:

In the furniture industry, aluminum profiles are popular for their modern aesthetics, lightweight design and versatility. They are commonly used in the manufacture of cabinets, shelving units and modular furniture systems. Aluminum profiles provide structural stability while allowing for creative design and can be customized to suit a variety of interior styles.

Renewable Energy Industry:

Aluminum extrusions play a vital role in the renewable energy sector, especially in solar panel mounting systems. The light yet strong nature of aluminum makes it ideal for building solar panel frames. Additionally, aluminum’s natural corrosion resistance ensures a long service life, making it suitable for outdoor installations.

In conclusion, as the industry continues to evolve, the need for innovative and sustainable materials continues to increase. Aluminum extrusions have proven to be game-changers, delivering exceptional strength, lightweight construction and environmental benefits across multiple industrial sectors. From aerospace to furniture, construction to renewable energy, the versatile applications of aluminum extrusions are reshaping the way industries work. As technology advances, we expect aluminum profiles to be more widely used in various fields, further strengthening its position as the material of choice for industry.

Welcome walk close to Ruiqifeng to get more information about aluminium extrusion.

Post time: Aug-18-2023