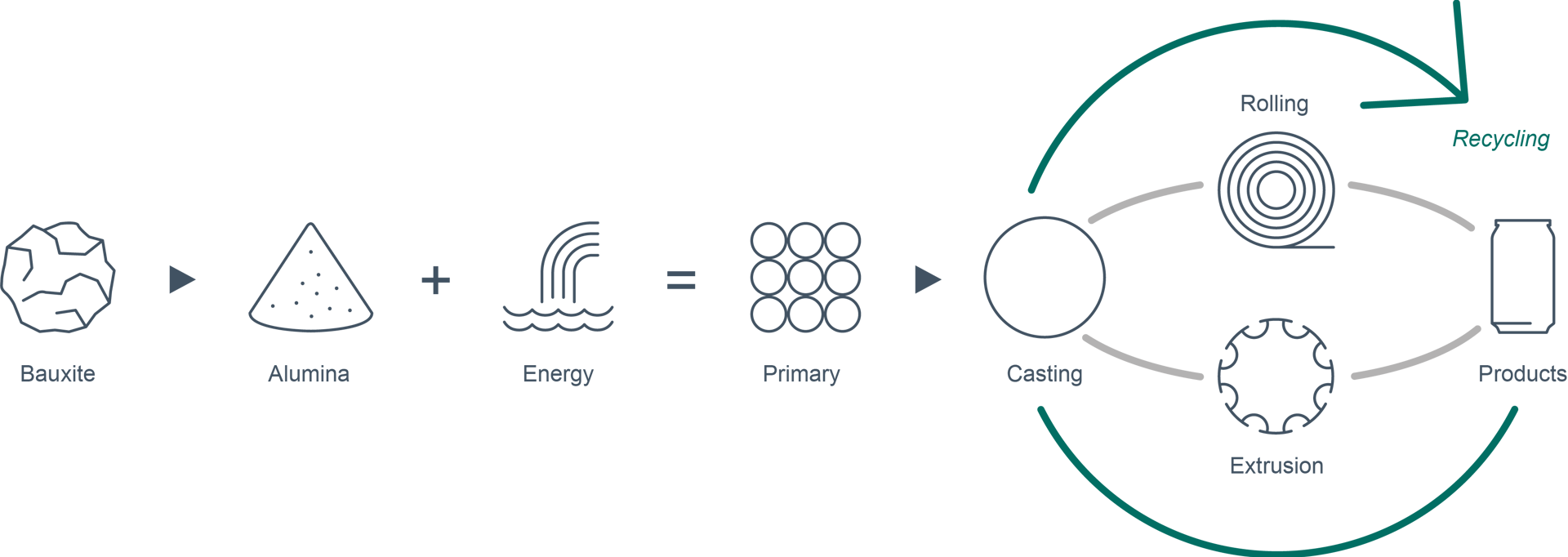

Aluminum stands out among other metals with its unparalleled life cycle. Its corrosion resistance and recyclability make it unique, as it can be reused multiple times with extremely low energy consumption compared to virgin metal production. From initial bauxite mining to the creation of customized products and subsequent recycling processes, our fully integrated aluminum company creates value throughout the entire cycle.

Aluminium value chain

1. Bauxite mining

The process of aluminium production originates from the mining of bauxite, an ore that contains approximately 15-25% aluminium and is predominantly located in regions around the equator. Currently, there are estimated reserves of 29 billion tonnes of bauxite that can sustain extraction for over a century at the present rate. Furthermore, the existence of undiscovered resources suggests the potential to extend this timeframe to 250-340 years.

2. Alumina refining

Using the Bayer process, alumina (aluminium oxide) is extracted from bauxite in a refinery. The alumina is then used to produce the primary metal at a ratio of 2:1 (2 tonnes of alumina = 1 tonne of aluminium).

3. Primary aluminium production

To produce aluminum metal, the chemical bond between aluminum and oxygen in alumina needs to be broken through electrolysis. This is a highly energy-intensive process that takes place in large-scale production facilities, requiring a significant amount of electricity. In order to achieve our goal of becoming carbon neutral from a lifecycle perspective by 2020, it is crucial to utilize renewable sources of power and consistently enhance our production techniques.

4. Aluminium fabrication

Aluminum processing is a process in which aluminum materials are processed and treated through a series of processes to manufacture various aluminum products. The main steps include extruding, rolling and casting. Extrusion creates pressure by passing aluminum material through a die in an extruder, extruding it into a material with the desired cross-sectional shape. This method is suitable for manufacturing complex-shaped products such as window frames, door frames and pipes. Rolling is to pass aluminum blocks or plates through a series of rolling processes through a roller mill to process them into the required thickness and width. This method is suitable for the production of products such as aluminum foil, aluminum alloy sheets and aluminum bottles. Casting involves pouring molten aluminum into a mold, which is then cooled and solidified to form the desired product shape. This method is suitable for manufacturing aluminum gears, engine parts, and automotive components, among others. Through these processing steps, aluminum materials can be accurately processed into a variety of aluminum products with different uses.

5. Recycling

Aluminium recycling is incredibly energy-efficient, utilizing only 5% of the energy needed to produce primary aluminium from raw materials. Furthermore, the process of recycling aluminium doesn’t degrade its quality, allowing it to be reused indefinitely. In fact, an impressive 75% of all the aluminium ever produced is still in active use today. These statistics highlight the sustainability and longevity of aluminium as a recyclable material in various industries.

Ruiqifeng can provide varies aluminium products to meet your needs. If you’d like to speak to our team and learn more about how Ruiqifeng can benefit your business, feel free to contact us.

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Oct-12-2023