How can production management be improved? What is production management needs and importance?

By Ruiqifeng Aluminum at www.aluminum-artist.com

To enhance the competitiveness of enterprises, it is necessary to strictly control production costs and eliminate all kinds of unnecessary waste generated in production, i.e. to achieve lean site management, whose main countermeasures are as follows. -1-

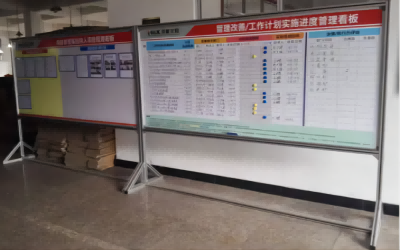

Strengthen the production plan control and realize visualized management

The production plan should be made with foresight, and the decomposition of the production plan target should be specific and scientific, in line with the actual situation of production, so as to reduce the number of changes of equipment parameters in production units and improve the efficiency of equipment utilization. Using visualized management in the production site organization to promote the effective implementation of the plan. Visualized management is the use of intuitive image, appropriate color to a variety of visual perception of information to organize on-site production activities, to improve labor production, it is based on visual signals as the basic means, as more as possible, to show the requirements and intentions of managers for everyone, so as to promote independent management, self-control. The manager should inform each producer of the production plan, order status, daily production status, and abnormal status in the form of a signboard, so that everyone can participate in the management. Hang the production board in the appropriate place of the production line for each period of time, and use the daily production form team leader to fill in the order input and output to guide the production of each department.

-2-

Conduct work efficiency analysis of operations.

Strengthen staff training efforts and standardize staff operations

Ineffective labor not only increases the labor intensity of operators, but also reduces labor efficiency and can easily lead to safety accidents. Ergonomics analysis of operations is to decompose the operation behavior of employees, eliminate the unreasonable and redundant actions in the process of operation, find out the standard of operation, and train the staff according to this standard. By standardizing the operation behavior of employees, the labor efficiency of employees can be improved, labor costs can be reduced, and the utilization rate of equipment can be improved, and the economic efficiency of enterprises can be improved.

-3-

Strengthen the management of setting and improve the operation efficiency

Placement management is a scientific management method to scientifically analyze and study the relationship between people, things and places in the production site, so that they can achieve the best combination, which takes the scientific placement of things in places as the premise, takes the complete information system as the medium, and takes the effective combination of people and things as the purpose. By organizing and reorganizing the production site, we remove the unwanted items from the production and put the needed items in the specified position, so that they are available at hand, and fundamentally eliminate the waste of handling and ineffective actions. Specifically, according to the purpose of production activities, considering the efficiency, quality and other constraints of production activities and the special requirements of the items themselves, we divide the appropriate place to place the items, determine the state of placing the items in the place, and serve as the information medium for the contact between people and items of the main body of production activities, so as to facilitate the combination of people and things and carry out production activities effectively. Placement management must first solve the problem of effective combination of people and things, which requires analysis of the state of combination of people and things. The result of placement management is to make scientific and reasonable placement arrangement for various sites, and finally complete the design of the placement map and the design of the information medium.

-4-

Strengthen the quality control of production process, and Reduce the rate of non-conforming products

Site management must strictly control the quality of work-in-progress to ensure a reasonable product qualification rate. Non-conforming products waste valuable human and material resources, but cannot be sold in the market. Moreover, it costs manpower and material resources to deal with non-conforming products. Quality control is an important function of site management. First of all, we should reasonably decompose the product quality index, clarify the quality responsibility of each production process, and ensure the product quality of finished products through the completion of each process quality index. Emphasize that quality is produced rather than inspected, and the final quality is ensured by process quality management. Secondly, to strengthen the quality control of the whole production process, each process requires that no defective products are made and do not flow into the later processes. Again, for the quality control of the unexpected situation, identify the cause in a timely manner, eliminate the non-conforming products in the bud. Finally, cultivate the quality consciousness of each employee, to ensure timely detection of quality problems, and constantly educate the field personnel on quality, so that they attach great importance to quality in mind, and in management they can master the quality management methods appropriately in their work, and have a high level of technical operation.

-5-

Establishing performance reward and punishment and remuneration system.

Improve the motivation of employees

In the field management, the first-line supervisor plays an important function of basic supervision, motivation, performance feedback and training. Do a good job of employee performance evaluation and feedback, carry out heart-to-heart activities timely with the employees with poor performance , helping them to improve their performance measures, performance assessment, the completion of job goals and tasks as the assessment criteria, routine assessment, the implementation of daily behavior and processes as the assessment criteria, are used as the basis for performance rewards and punishments and pay. The interests of the employees of the enterprise are linked to the results of the enterprise goals, improve the motivation and efficiency of the employees, achieve effective cooperation and positive interaction between different workshop, only then the production efficiency can be utilized to the best level.

Ask a free consultant and request for a quick quote! ( www.aluminum-artist.com)

Post time: Oct-20-2022