When you are looking to solve your product design needs with extruded aluminum solutions, you should also find out which temper range best suits your needs. So, how much do you know about aluminum temper? Here is a quick guide to help you.

What are aluminium alloy temper designations?

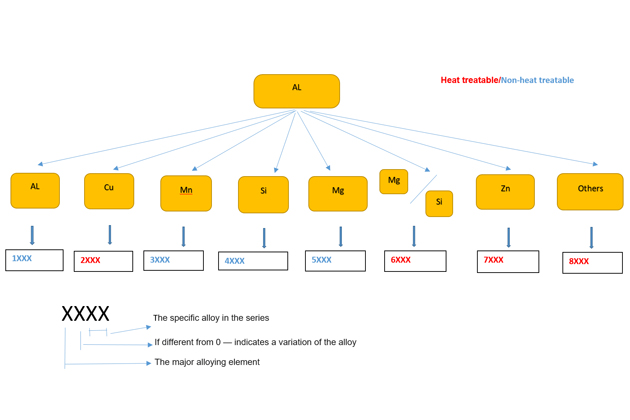

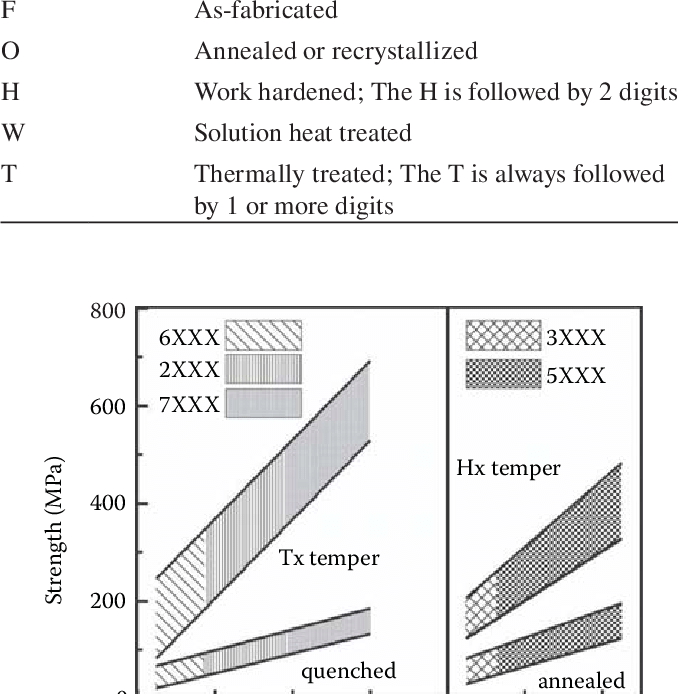

The state designation represents the change in physical properties that can be achieved in the alloy. The alloys we extrud, such as wrought aluminum alloys, are divided into two categories: heat treatable and non-heat treatable. The 1xxx, 3xxx and 5xxx series are not heat treatable, while the 2xxx, 6xxx and 7xxx series are heat treatable. The 4xxx series contains both types. Non-heat treatable alloys cannot be significantly strengthened by heat treatment and instead rely on the degree of cold working to improve their properties. Heat-treatable alloys, on the other hand, can be strengthened by heat treatment. These differences in chemical and metallurgical structure also affect how the alloy reacts during welding and other manufacturing processes. Essentially, the wide variety of aluminum alloys and their tempering states creates a complex family of materials, and understanding these fundamental differences can lead to greater success.

Five aluminium alloy temper designations

Understanding the condition designations is critical to understanding the properties and form of aluminum products. These designations are alphanumeric and added to the alloy name to provide information on how the alloy is mechanically and/or thermally treated to obtain the desired properties. For example, 6061-T6 represents a specific status name. The first character in a temper name (F, O, H, W, or T) indicates the general handling category.

F-state products are semi-finished products that require further processing to obtain the finished shape or state.

O indicates annealed products to maximize workability or increase toughness and ductility.

H stands for strain-hardened non-heat-treatable alloy.

W is suitable for naturally aged alloys after solution heat treatment.

T refers to the product form of any heat-treatable alloy that has been solution heat treated, quenched, and aged. Recognizing and understanding these condition designations is critical for producers and users to understand the processing history and characteristics of aluminum products.

How tempers impact your product

End users must understand these designations in detail to avoid compromising critical functionality provided by the manufacturer later in the process. For example, optimizing the mechanical properties of a heat-treatable alloy requires selecting the appropriate solution heat treatment, quenching rate, and aging treatment sequence. This can enhance corrosion resistance at the expense of strength. In addition, tempering of the alloy can affect the appearance of the product after anodization due to the reaction of the alloy to the process. Understanding the various aluminum alloys and states and the mechanical properties they offer can be challenging, especially for structural engineers who are accustomed to working with steel. Still, it’s crucial, and I hope this quick guide on temper designation is a step in the right direction.

If you want to know more, or have any questions, feel free to contact us!

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Jul-05-2024