Aluminum extrusion is a widely used manufacturing process that involves shaping aluminum by forcing it through formed openings in a die. The process is popular due to aluminum’s versatility and sustainability, as well as its low carbon footprint compared to other materials. However, the production of aluminum still produces significant amounts of carbon dioxide emissions, which has an impact on the environment.

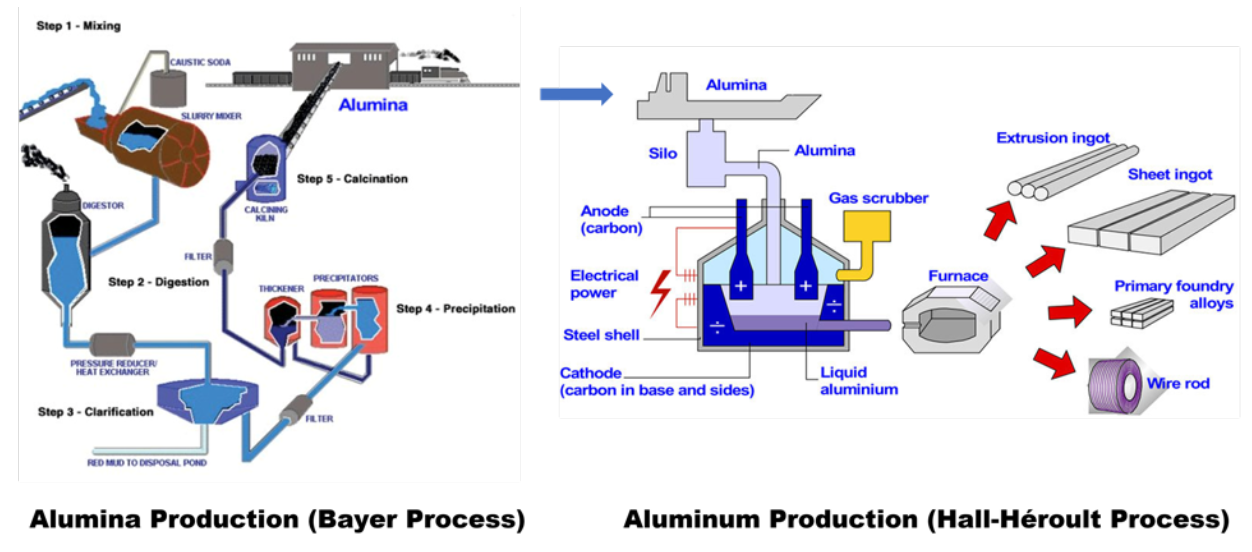

The production of aluminum involves the extraction of bauxite ore, which is then refined into alumina, which is then smelted into aluminum. The process is energy-intensive and releases carbon dioxide, increasing the industry’s carbon footprint. In fact, the aluminum industry emits approximately 1% of global CO2 emissions.

To address the environmental impact of aluminum production, efforts are being made to reduce the industry’s carbon footprint. One approach is to focus on developing low-carbon aluminum production methods. This involves using renewable energy sources such as hydropower or solar power to power the smelting process, thereby reducing reliance on fossil fuels and lowering CO2 emissions.

In addition, technological advancements have increased the efficiency of aluminum production, thereby reducing energy consumption and lowering CO2 emissions per ton of aluminum. Recycling aluminum also plays a vital role in reducing the industry’s carbon footprint, as recycling aluminum requires significantly less energy compared to primary production, resulting in significant reductions in CO2 emissions.

Historical and projected primary and recycled aluminum production has grown and is growing from 1950 to 2050,and the proportion of recycled aluminum is increasing (Credit: IAI Material Flow Update)

Furthermore, the use of aluminum extrusion in various industries offers sustainability advantages as it is lightweight, durable and fully recyclable. This contributes to the circular economy by promoting the reuse of aluminum products and reducing the need for primary production.

In conclusion, while the production of aluminum does generate CO2 emissions, the industry has been actively working to reduce its carbon footprint. The development of low-carbon aluminum production methods, improvements in energy efficiency and the promotion of aluminum recycling all contribute to the sustainable development and environmental friendliness of the aluminum industry. By continuing to prioritize these efforts, the industry can further mitigate its environmental impact and contribute to a greener future.

If you want to know more, or have any questions, feel free to contact us!

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Jun-11-2024