Aluminum profile windows and doors are commonly used in modern buildings, and their quality directly affects the lifespan, safety, and user experience. So, how can we distinguish high-quality products from a wide range of aluminum profile windows and doors? This article will provide professional guidance on how to identify the quality of aluminum profile windows and doors from various aspects, including material quality, processing technology, performance testing, accessories selection, brand and certification, and regional requirements.

1. Material Quality Identification

Aluminum profiles are the core component of windows and doors, and their quality directly determines the performance of the product. Here are the key points for identifying the quality of aluminum profiles:

- Aluminum Alloy Grade: High-quality windows and doors use 6063-T5 or higher-grade aluminum alloys, which offer high strength, excellent corrosion resistance, and oxidation resistance.

- Wall Thickness: According to national standards (GB/T 5237), the wall thickness of the main profiles should not be less than 1.4mm, with some high-end products reaching 2.0mm or more.

- Surface Treatment: High-quality aluminum profiles typically undergo anodizing, electrophoretic coating, or powder coating, with smooth surfaces, uniform color, and weather resistance.

Supporting Data: According to the China Nonferrous Metals Industry Association, high-end aluminum profiles’ surface treatment has a weather resistance of up to 20 years, and corrosion resistance is improved by over 30%. Additionally, Ruiqifeng’s technology ensures high-quality surface treatment: powder coating thickness ranges from 60 to 80 microns; anodizing thickness ranges from 5 to 25 microns, with industrial anodizing being 10 to 20 microns, ensuring no color change for 10 years.

Tip: By tapping on the aluminum profile, you can listen for a clear sound to initially determine the material’s density and quality.

2. Processing Technology Identification

Fine processing technology guarantees the high quality of windows and doors. Observe the following points:

- Cutting Precision: High-quality profiles should be cut neatly, with no burrs or significant gaps.

- Assembly Firmness: The frame connections should use corner brackets or screws to ensure that they are secure and not loose.

- Sealing: Check whether the weatherstrips are uniformly adhered without any curling, cracks, or detachment.

Professional Tip: When opening and closing the windows and doors, feel their smoothness. High-quality products often use silent rollers and precision profiles, ensuring smooth sliding.

Case Study: Ruiqifeng uses high-precision CNC machining technology, controlling profile assembly error to within 0.1mm, greatly improving air tightness.

3. Performance Testing

Performance testing is the scientific basis for evaluating product quality. The following indicators are crucial:

- Wind Pressure Resistance: High-quality aluminum profile windows and doors can withstand significant wind pressure without deformation, making them ideal for high-rise buildings.

- Air Tightness: Check whether there is any air leakage when the windows and doors are closed. High-quality products adopt multi-seal designs, ensuring better airtightness.

- Water Tightness: Conduct a water spray test to check if the windows and doors leak. High-quality products typically have drainage channels to prevent water penetration.

- Sound Insulation: Windows and doors with hollow glass paired with aluminum profiles offer better sound insulation, meeting modern residential needs for quiet environments.

Reference Data:

- International standard ISO 140 specifies that high-quality aluminum profile windows and doors should have a sound insulation performance of Rw ≥ 34dB.

- According to the European EN 12208 standard, high-performance windows and doors should have a water tightness class of 9A.

4. Accessories Selection

The hardware accessories of aluminum profile windows and doors play a key role in their durability and user experience. Key components include:

- Rollers: High-quality rollers are typically made from stainless steel or high-strength nylon, offering wear resistance and quiet operation.

- Handles: The material, feel, and secure fastening of handles determine the comfort of operating the windows and doors.

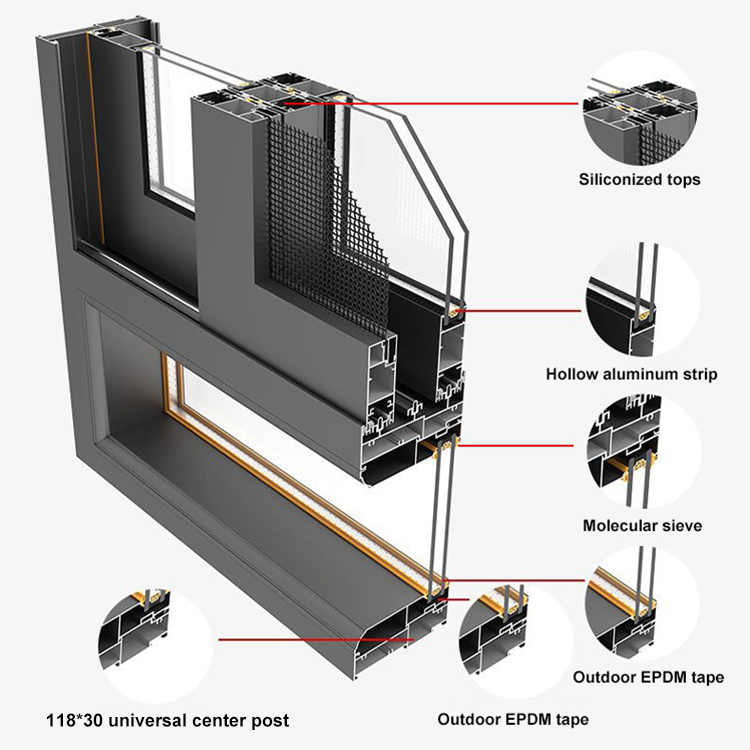

- Sealing Strips: Sealing strips made from EPDM or silicone offer good flexibility and excellent aging resistance.

- Glass: High-quality aluminum profile windows and doors are usually paired with tempered or laminated glass, enhancing safety, sound insulation, and thermal performance.

Example: The high-end accessories of German brand Schüco use patented technology, and their handles have passed 100,000 tests without loosening, significantly enhancing the durability of the product.

5. Appearance Design and Aesthetics

The appearance of windows and doors directly affects the overall aesthetic of the building. The following are characteristics of high-quality windows and doors:

- Uniform Coating: There should be no color differences or bubbles, and the anodized aluminum profile surface should have a high gloss.

- Modern Design: Profile designs should be ergonomic and feature a minimalist, stylish appearance.

- Variety of Color Options: High-quality windows and doors offer various color options, such as powder-coated wood grain and metallic finishes, to meet individual preferences.

Supporting Data:

- A market survey conducted by Statista found that over 60% of consumers prioritize appearance when choosing windows and doors, indicating that aesthetics play an important role in purchasing decisions.

- High-end anodized aluminum profiles maintain color stability for over 10 years.

6. Brand and Certification

Choosing products from reputable brands and certified windows and doors ensures better quality:

- ISO 9001 Certification: Ensures standardized production processes.

- CE Certification: Meets EU market safety standards.

- Brand Reputation: Check customer reviews and market feedback to choose reputable brands.

Famous Brands:

- Schüco (Germany): Known for high-end, energy-efficient products, particularly suitable for extreme climate conditions.

- Reynaers (Belgium): Famous for innovative profile designs and excellent thermal performance.

- YKK AP (Japan): Specializes in high air tightness and sound insulation products.

- Ruiqifeng (China): Offers customized aluminum profile solutions to meet diverse needs.

7. Market Demand Analysis by Region

- Europe: Focuses on energy efficiency and environmental friendliness, requiring windows and doors to have high thermal insulation and recyclability.

- Middle East: Emphasizes wind pressure resistance and high-temperature performance, ideal for large glass curtain wall designs.

- North America: Prioritizes safety and sound insulation, commonly using laminated glass windows and doors.

- Southeast Asia: Focuses on moisture resistance and corrosion resistance, suitable for high humidity environments.

Example: The Burj Al Arab in Dubai selected Schüco windows and doors, using products with wind pressure resistance rating of 9A, perfectly suited for the extreme desert climate.

8. Conclusion and Recommendations

To identify the quality of aluminum profile windows and doors, a comprehensive evaluation of materials, technology, performance, and accessories is necessary. For general consumers, directly checking profile wall thickness, surface treatment, and hardware accessories can help assess quality. For professional buyers, it is essential to consider performance testing data and brand certification information.

Recommendations:

- For residential users, choose products with good airtightness and sound insulation.

- For high-rise buildings or coastal environments, focus on wind pressure resistance and corrosion resistance.

- When purchasing, ask the manufacturer for performance test reports to ensure the product meets expectations.

By following these methods, you can choose high-quality aluminum profile windows and doors that will enhance your living experience while ensuring safety and durability.

Post time: Jan-23-2025