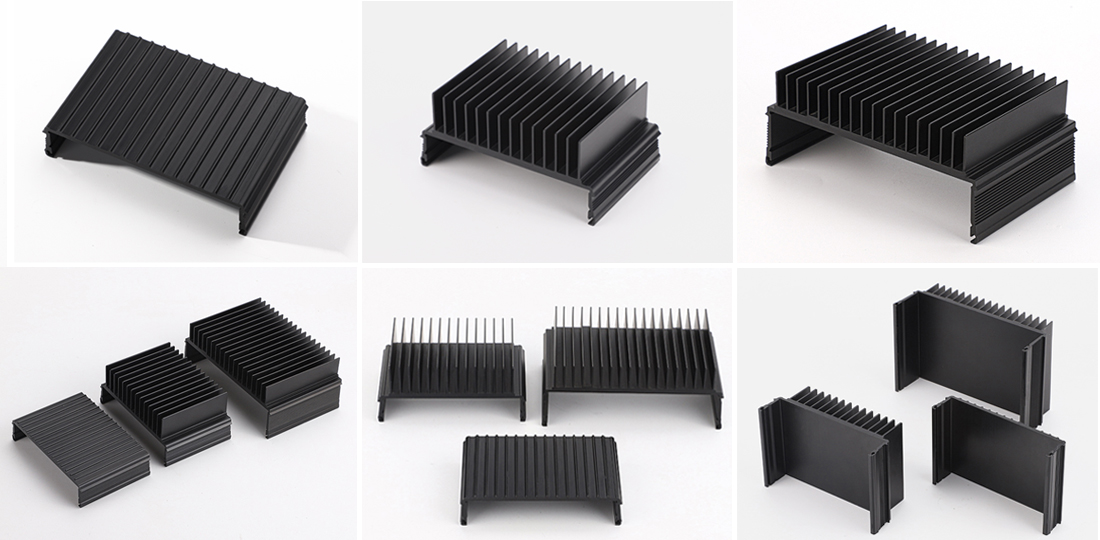

Aluminium is a popular choice for heat sinks due to its excellent thermal conductivity and lightweight properties. Heat sinks play a crucial role in dissipating heat generated by electronic components, preventing overheating and ensuring optimal performance. However, there are several ways to further enhance the thermal performance of aluminium heat sinks. In this article, we will explore some of these methods to improve the efficiency of heat sinks.

How aluminum heat sinks work?

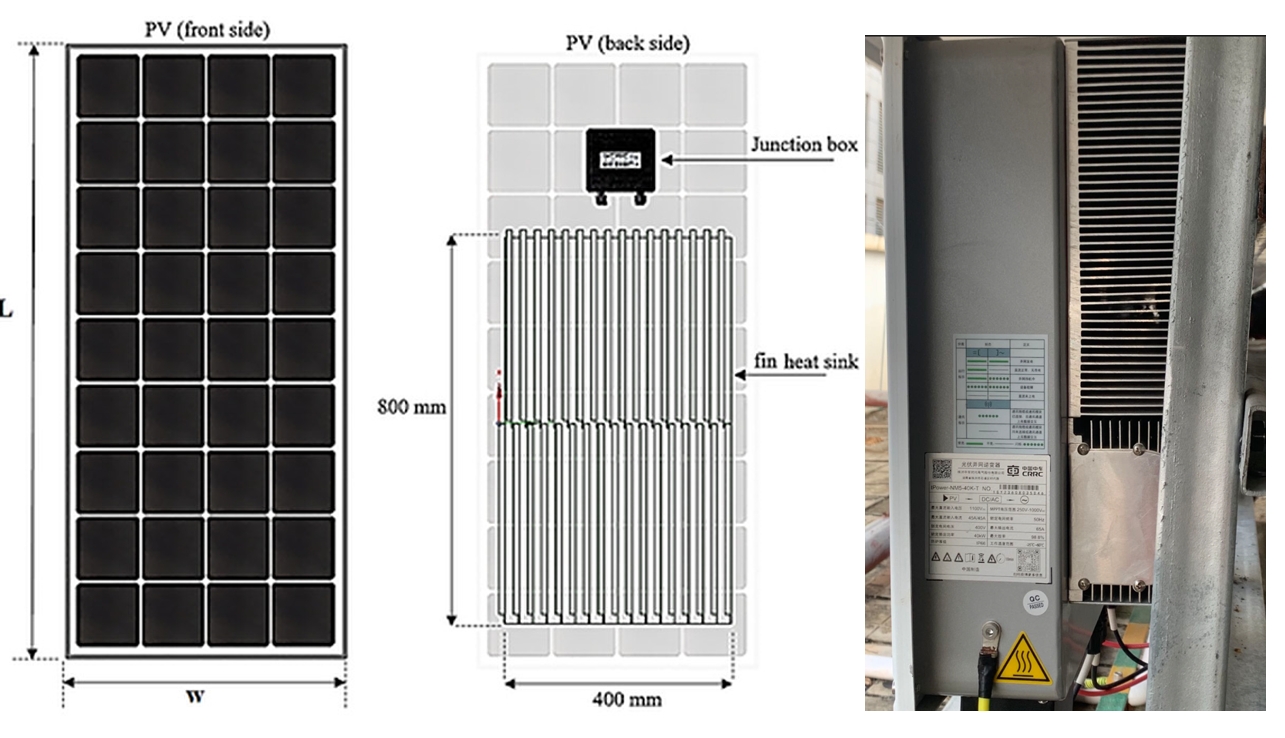

Aluminium heat sinks work by utilizing the high thermal conductivity of aluminium to transfer heat away from a heat-generating component. The heat generated by the component is conducted into the aluminium heat sink through direct contact. The heat is then dissipated into the surrounding air through a process called convection. The shape and design of the heat sink, with fins and channels, increase its surface area, allowing for more efficient heat transfer. As the heat is conducted from the component to the heat sink, the heat sink’s large surface area exposes a larger area to the surrounding air, enhancing the transfer of heat. Additionally, heat sinks often incorporate fans or other cooling mechanisms to further enhance heat dissipation. These fans or coolers help to increase airflow, improving convection and effectively cooling the component.

How to improve the thermal performance of aluminium heat sinks?

Improving the thermal performance of a heat sink depends on the design of the solution and on a handful of other factors. They tie together. Let us go through these factors, which might enable you to improve the design of your heat sink and achieve the performance you need.

Aluminium heat sinks are usually air-cooled or liquid-cooled. Regardless of whether yours uses liquid or air cooling, the main factors that impact its thermal performance include air or liquid flow and fin/channel design. Other factors to consider in the design phase:

• Surface treatment

• Thermal resistance

• Joining methods

• Materials, including the thermal interface material

• Costs

The most common heat sink materials are aluminium alloys in the 6000-series, primarily the 6060, 6061 and 6063 alloys. The thermal conductivity values of these alloys are solid. Their thermal properties are not as good as those of copper, but an extruded aluminium heat sink weighs about half as much as a copper conductor having the same conductivity, and the aluminium solution does not cost as much, either.

Ruiqifeng has rich experience in the design and production of aluminium heat sinks, feel free to contact us.

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Post time: Nov-18-2023