What are the standards of solar panels? How high they are?

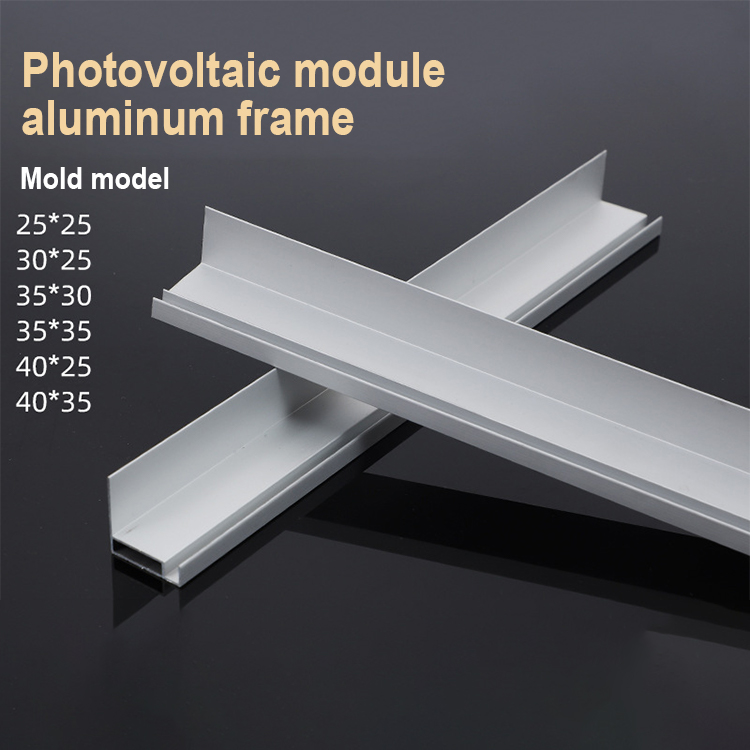

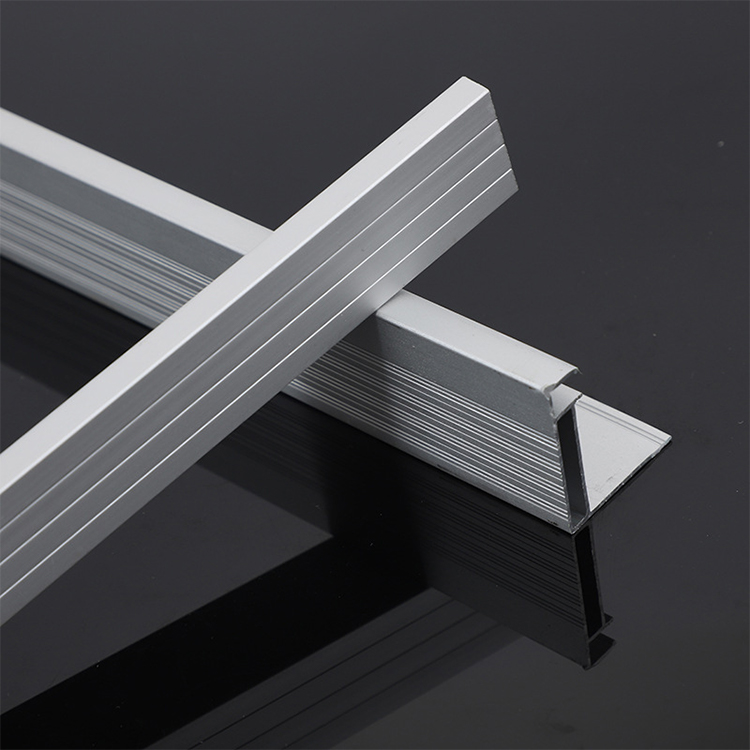

Solar aluminum panels belong to the category with relatively high requirements in aluminum products, and its mechanical properties, dimensional tolerance and appearance are higher than those of ordinary industrial and architectural profiles. In addition, in order to comply with the development trend of cost reduction and energy saving of photovoltaic modules, the solar panel is becoming thinner and thinner, which is a big challenge to the mechanical properties. So how high is the requirement of solar aluminum frame now? Let’s take a closer look:

1. In terms of mechanical properties, the hardness should reach 15hw, and the hardness of ordinary industrial aluminum profiles is generally about 10hw. The tensile strength is more than 240mpa, and the yield strength is more than 200MPa. It is good that the tensile strength of ordinary industrial aluminum profiles reaches 180MPa. Because 6063 aluminum alloy can’t reach such high strength no matter how to deal with it, 6005 aluminum alloy is mostly used for solar frame now.

2. In terms of dimensional tolerance, the solar panels have high requirements for length tolerance and cutting angle. The angle tolerance of profile section should be controlled within 5 degrees, and the bevel angle should even be controlled within 3 degrees. The bending and twisting degree shall be controlled at 1mm / m. The section size shall be controlled within ± 0.3mm, and the special size requirements are higher.

3. In terms of appearance, the overall color should be consistent without color difference; The surface is not allowed to have scratches, bright lines, black lines, bumps, extrusion lines and other defects; The sand blasting on the surface shall be uniform and fine, and there shall be no missing spraying. For industrial aluminum profiles, extrusion lines are a normal phenomenon.

Post time: Aug-01-2022