What Do You Know About the Aluminium Extrusion Dies?

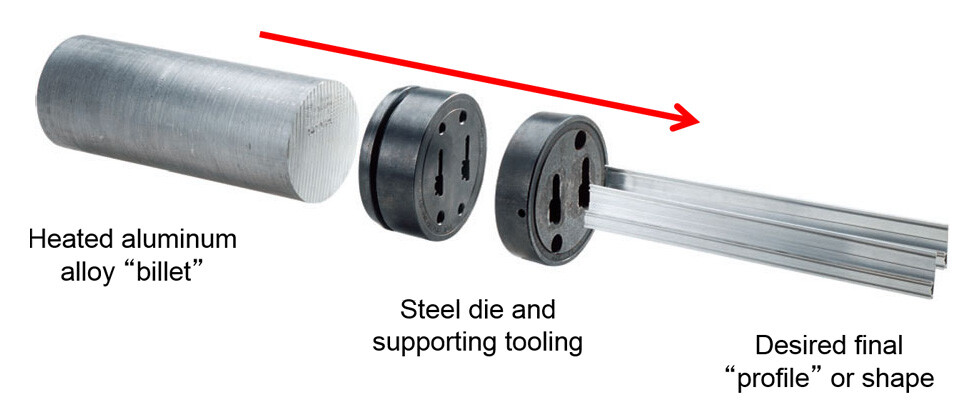

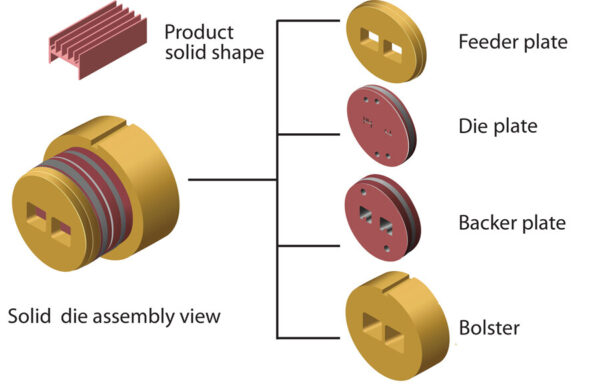

Aluminium extrusion dies are an essential component in the process of shaping aluminium into various profiles and shapes. The extrusion process involves forcing aluminium alloy through a die to create a specific cross-sectional profile. The die itself is a specialized tool that determines the final shape of the extruded aluminium product.

Aluminium extrusion dies are typically made from high-quality tool steel or, in some cases, carbide. These materials are chosen for their durability and ability to withstand the high temperatures and pressures involved in the extrusion process. The dies are precision-machined to the exact specifications of the desired profile, ensuring that the extruded aluminium product meets the required dimensional tolerances.

The design of the extrusion die is a critical factor in determining the quality and characteristics of the final product. The die must be carefully engineered to control the flow of the aluminium alloy and prevent defects such as surface imperfections, warping, or cracking. The shape and dimensions of the die’s opening dictate the cross-sectional profile of the extruded product, whether it be a simple rod, a complex structural shape, or a custom-designed profile for a specific application.

The process of creating an aluminium extrusion die begins with the design phase, where engineers use computer-aided design (CAD) software to develop the die’s geometry. This involves considering factors such as material flow, cooling, and the desired profile’s specific requirements. Once the design is finalized, the die is manufactured using precision machining techniques such as milling, grinding, and electrical discharge machining (EDM) to achieve the required level of accuracy and surface finish.

After the die is manufactured, it undergoes a series of heat treatments and surface coatings to enhance its durability and resistance to wear. These treatments are crucial for ensuring the die’s longevity and maintaining the quality of the extruded products over time.

Aluminium extrusion dies are also subject to regular maintenance and refurbishment to ensure consistent product quality and extend the die’s lifespan. Wear and tear from the high pressures and temperatures involved in the extrusion process can lead to die erosion, dimensional changes, and surface damage. As a result, die maintenance may involve processes such as polishing, re-machining, or even complete die refurbishment to restore the die to its original specifications.

In conclusion, aluminium extrusion dies are a critical component in the production of a wide range of aluminium products, from simple shapes to complex profiles used in various industries. The design, manufacturing, and maintenance of these dies are essential to achieving high-quality, precision-engineered extruded aluminium products that meet the stringent requirements of modern applications. As technology continues to advance, the development of innovative die designs and materials will further enhance the capabilities and efficiency of the aluminium extrusion process.

Shall you have any questions on aluminium extrusion, please feel free to reach us at any time.

Post time: Jun-07-2024