What Is 6 Series Aluminum Alloy And Its Application?

What is 6 series aluminum alloy?

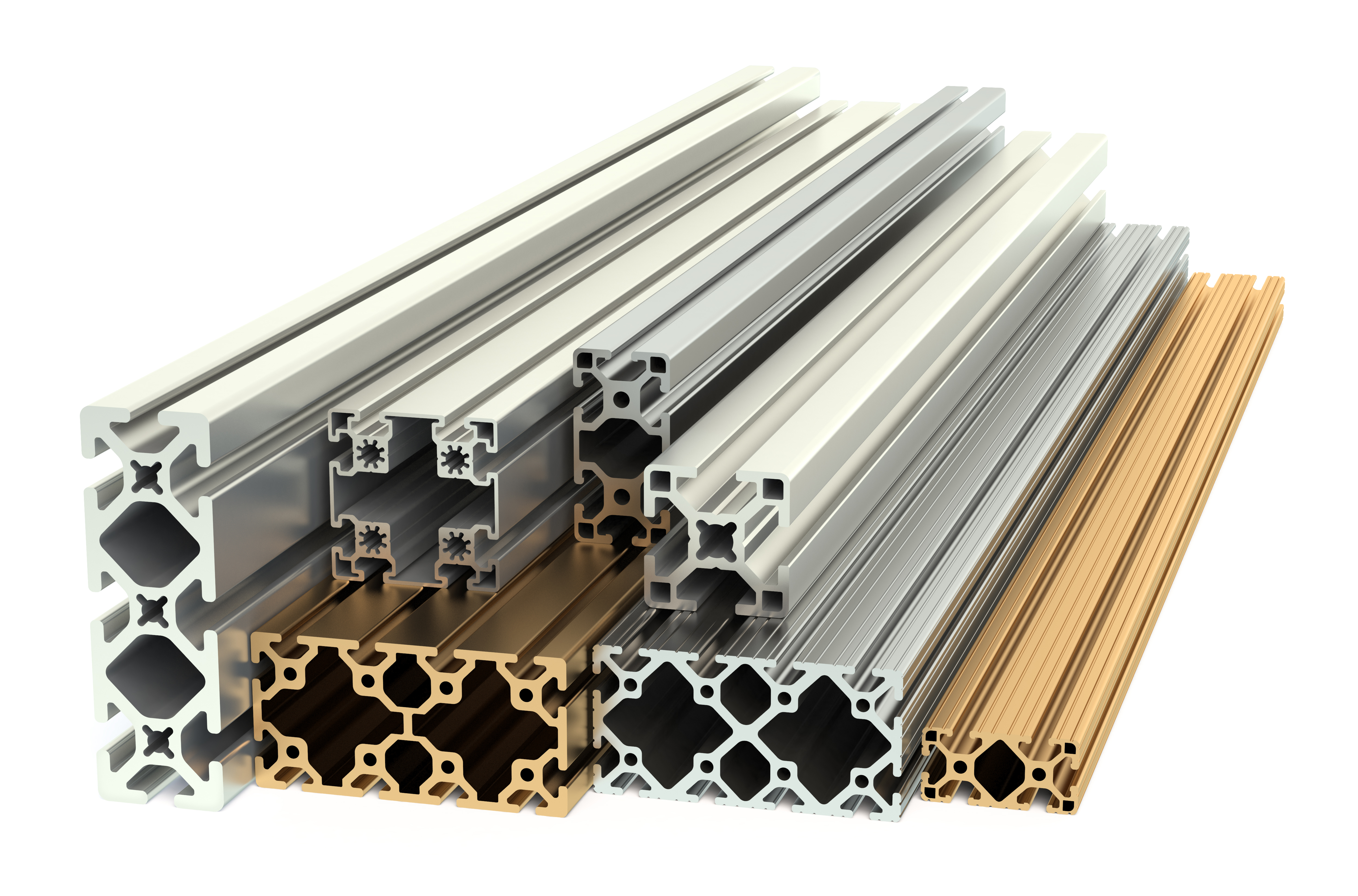

The 6 series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloying elements and Mg2Si phase as the strengthening phase, which belongs to the aluminum alloy that can be strengthened by heat treatment. The alloy has the advantages of medium strength, high corrosion resistance, no tendency of stress corrosion cracking, good welding performance, constant corrosion performance of welding zone, good formability and process performance, etc. When the alloy contains copper, the strength of the alloy can be close to that of the 2 series aluminum alloy, and the process performance is better than that of the 2 series aluminum alloy, but the corrosion resistance becomes worse, and the alloy has good forging performance. Among the 6 series alloys, 6061 and 6063 alloys are the most widely used. They have the best comprehensive properties. The main products are extruded profiles, which are the best extruded alloys. The alloys are widely used as building profiles.

At present, 6 series of aluminum alloy grades are produced: 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02. The following will introduce their respective uses in detail.

The main application of 6 series aluminum alloy:

6005: Extruded profiles and pipes, used for structural parts that require a higher strength than 6063 alloys, such as ladders, TV antennas, etc.

6009: Automobile body panels.

6010: Sheet for Automobile bodies.

6061: requiring various industrial structures with certain strength, high weldability and corrosion resistance, such as pipes, rods, profiles, plate.

6063: Industrial profiles, architectural profiles, irrigation pipes and extruded materials for vehicles, benches, furniture, fences, etc.

6066: Extruded materials for forgings and welded structures.

6070: Extruded materials and pipes for heavy-duty welded structures and the automotive industry.

6101: High-strength rods, electrical conductors and cooling equipment for buses, etc.

6151: Used for die forging crankshaft parts, machine parts and rolling rings, for applications that require good forgeability, high strength and good corrosion resistance.

6201: High-strength conductive rods and wires.

6205: Thick plates, pedals and high-impact extrusions.

6262: Threaded high-stress parts requiring better corrosion resistance than 2011 and 2017 alloys.

6351: Extruded structural parts of vehicles, pipelines for water, oil, etc.

6463: Construction and various appliance profiles, as well as automotive decorative parts with bright surfaces after anodizing.

6A02: Aircraft engine parts, forgings and die forgings with complex shapes.

For more aluminum alloy knowledge, please contact Aluminum Specialist Rui Qifeng!

Post time: Mar-02-2023