What you should know about anodizing aluminium?

Aluminium is well-suited to anodizing, making it one of the most respected and commonly used materials for consumer, commercial and industrial products in comparison to other metals.

Anodising is the relatively straightforward electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish, now nearly a century old used to increase the thickness of the natural oxide layer on the surface of the aluminium. (Aluminium oxide is a durable compound that seals and protects the base metal.)

A hard durable finish that maintains the beauty and natural metallic lustre of aluminium while reinforcing its natural ability to withstand the elements, Anodising is an integral finish, that cannot flake, peel or blister. The controlled formation of an oxide layer which is much harder, more durable and about a thousand times thicker than the thin oxide layer naturally formed

1-Mill Finish Aluminum profiles hung on racks ready for anodizing

Other nonferrous metals, such as magnesium and titanium, can be anodized, but the composition of aluminium makes it ideally suited to the process.

The unique anodized finish is the only one in the metals industry that satisfies each of the factors that must be considered when selecting a high-performance aluminium finish that is required for luxury items and interior design such as loudspeakers, lighting, electronics, watches and trays.

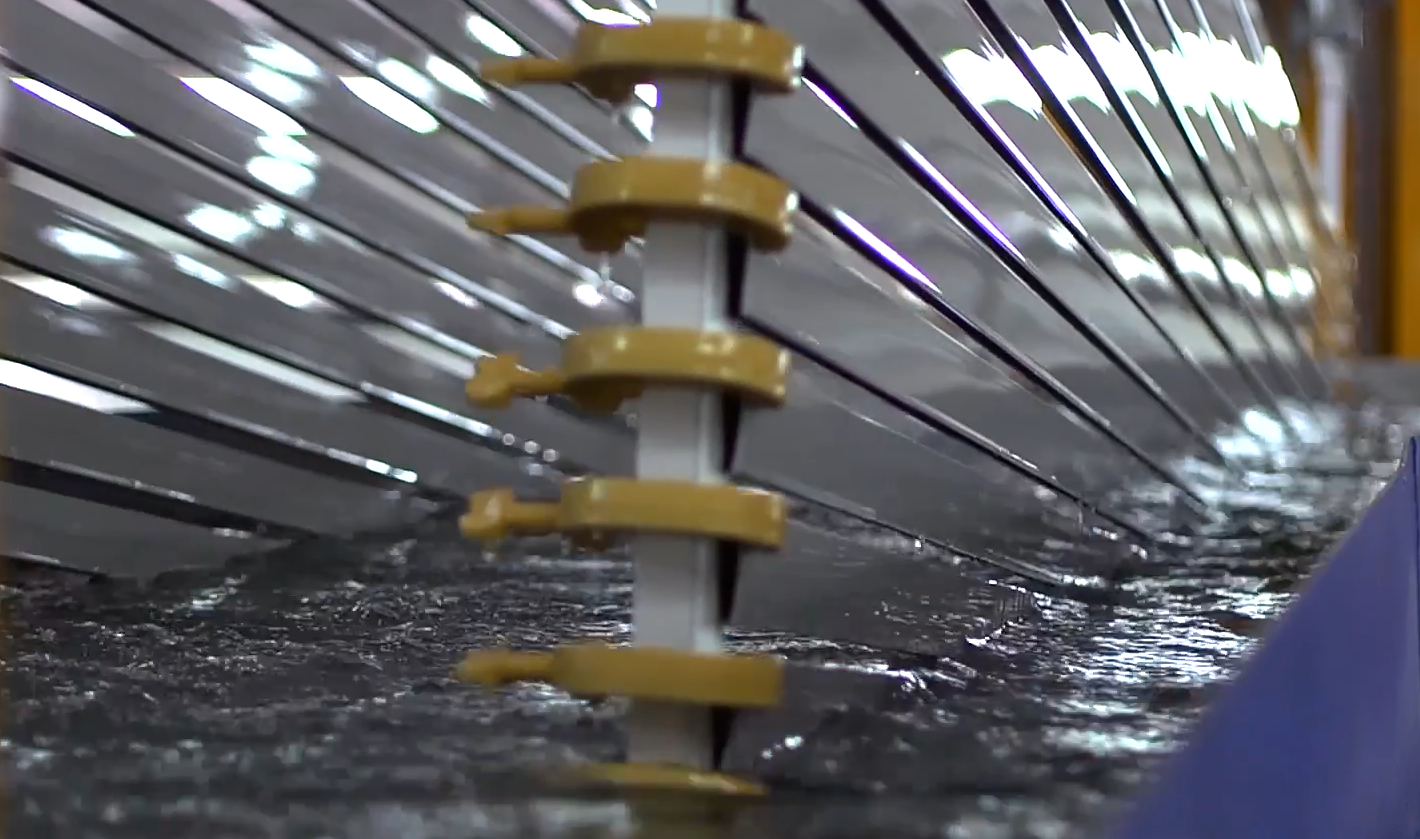

2-Anodizing tank

Aluminium anodizing

Anodizing is an electrochemical process which converts the surface of the metal into a long-lasting, high-performance aluminium oxide finish. Because it is integrated into the metal rather than just applied to the surface, it cannot peel or chip. This protective finish makes it very hard and durable and enhances its resistance to corrosion. Depending on the process, the anodized finish is the second-hardest substance known to man, exceeded only by the diamond.

The anodizing process is, in simplified terms, the highly controlled enhancement of a phenomenon that already occurs naturally: oxidation. The aluminium is immersed in an acid electrolyte solution through which attached electrodes pass an electric current at very low temperatures. The result is a high-performance, hardcoat surface. However, the metal remains porous so it can be colored and sealed, or undergo additional processing, if desired.

3-Ready for anodizing

Benefits of anodizing aluminium

Aluminium anodizing creates an extremely hard surface that can withstand extreme wear and tear. This includes industries such as military and defense, construction, applications such as elevator doors and escalators, and even home cookware. The primary benefits of anodizing aluminium include:

- 1. Durability, this method is unaffected by sunlight and mostly fade-resistant.

- 2. The finished product will enjoy a long lifespan and require little maintenance.

- 3. Stable color, the anodic coating will not peel or flake because it is actually part of the metal.

- 4. Easy to maintain – periodic cleaning with water and a mild detergent will restore its original lustre.

4-Anodizing Finish

Low maintenance

Evidence of wear or abrasions from the extrusion process, installation, or from frequent handling and excessive cleaning are rare. Anodized aluminium is easily restored to its original luster with gentle cleaning.

Beauty

Anodized aluminium maintains its metallic appearance but can easily accommodate color and gloss applications.

Value

Finishing costs and maintenance costs are low, giving anodized products a better value in the long term.

5-Anodized details

Cons of powder coating the surface of aluminium

- 1. The surface may become vulnerable to acidic pollutants in urban areas.

- 2. The translucence of this coating contributes to colour variation issues between batches – although this lack of uniformity has been reduced in recent times.

- 3. Anodised finishes are normally only available in a matt and polished finish.

- 4. Since anodised finishes can only be applied to aluminium, other building elements in a similar colour may look conspicuously different.

6-Anodized details

Contact us

Mob/Whatsapp/We Chat:+86 13556890771(Direct Line)

Email: daniel.xu@aluminum-artist.com

Website: www.aluminum-artist.com

Address: Pingguo Industrial Zone, Baise City, Guangxi, China

Post time: Jun-01-2024