PriceList for Aluminum Radiators Testing Machine - Black Anodized Aluminum Extruded Heat Sink – Ruiqifeng

PriceList for Aluminum Radiators Testing Machine - Black Anodized Aluminum Extruded Heat Sink – Ruiqifeng

PriceList for Aluminum Radiators Testing Machine - Black Anodized Aluminum Extruded Heat Sink – Ruiqifeng Detail:

| Place of Origin: | Guangxi | OEM: | Yes |

| Process: | Aluminum extrusion + Friction Welding | Temper: | T3-T8 |

| Material: | Aluminium Profile | Shape: | Square |

| Packing: | Standing Export Packing | Brand Name: | Ruiqifeng |

| Application: | IGBT | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | RQF003 | Tolerance: | 0.01 mm |

| Finish: | Clean+Anodized | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | 400*300*100 mm |

Product Details

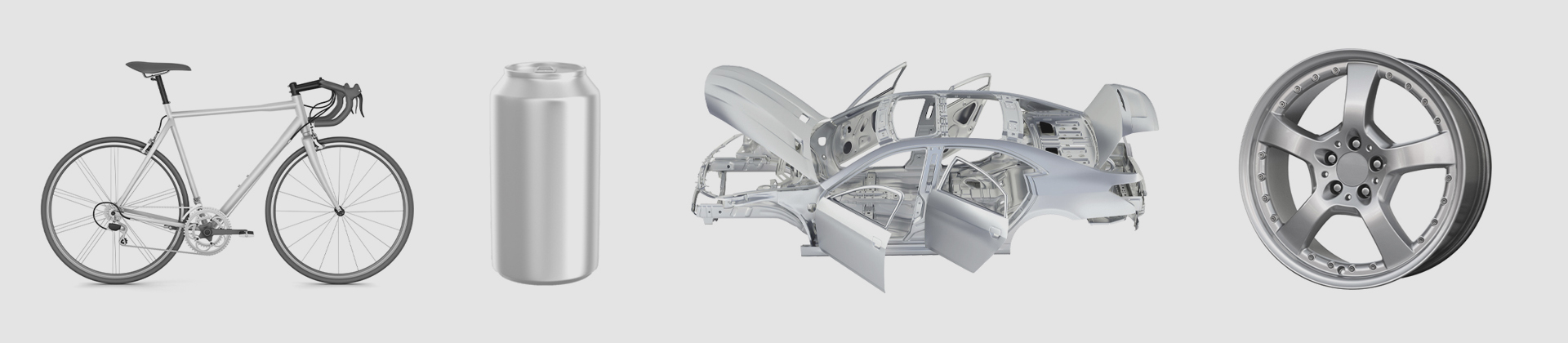

Ruiqifeng relying on long-term accumulated technical experience and production process sets aluminum alloy profiles with good thermal conductivity and other characteristics and develops a customized aluminum extruded heat sink that can meet customers’ requirements of product differentiation, specialization and personalization. The finished extruded heat sinks surface is anodized to improve the corrosion resistance, wear-resistance and appearance of aluminum. At present, the commonly used types of extruded aluminum heat sink in China are electronic heat sink, computer heat sink, sunflower heat sink, power semiconductor heatsink and so on. Because of their superior performance, extruded aluminum heat sinks are widely used in machinery, automobile, wind power, construction machinery, air compressor, railway locomotive, household appliances and other industries.

Product Features

This black anodized aluminum extruded heat sink is 260*125*50 mm, and we can provide some standard differernt sizes and shapes extruded heat sink for customer, There are 30,000+ sets standard molds in our stock for your option, saving your R&D cost. Also we can provide custom extruded heat sink design and manufacturing. We have more than 10 years professional manufacturing experience, more than 20 times aspect ratio heatsink can be extruded by 800 tons–5000 tons extruding machine by most advanced technology. Ultra wide extruded heatsink can be made by our unique friction welding technology. The production process for the extruded heat sinks are profiles extruding, cutting, CNC Machining(milling, drilling,tapping), deburring, cleaning, inspecting, packing. Surface Treatment included degreasing,(black) anodizing.

Product Application

Applied to Communication, UPS, inverter, controller, wind power converter, SVG telecommunication, LED Lighting, Power Supply Equipment, Electronic Industry,Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems,etc.

Product detail pictures:

Related Product Guide:

Ruiqifeng New Materials Co., Ltd. is a well-established aluminium profile extrusion factory with nearly two decades of experience in the industry. Our focus is on delivering high-quality aluminum wall curtain solutions to our valued customers. Equipped with state-of-the-art technology and processes, we ensure that our products are of excellent quality and highly competitive in the market.As a one-stop service provider, Ruiqifeng offers comprehensive support throughout the entire production process, from design and mold opening to production, shipment, and after-sales service. Our dedicated sales team possesses extensive experience and knowledge to guide our customers professionally and provide excellent customer service. Situated in Pingguo, Guangxi, our factory is located in an area abundant in aluminum ore resources. This allows us to produce aluminum profiles with exceptional quality at competitive prices for raw materials. We prioritize environmental protection and strictly adhere to relevant regulations and standards to ensure sustainable production practices. Every product undergoes rigorous testing and quality control to meet industry standards and customer expectations. Ruiqifeng has established collaborations with renowned companies such as YKK, Fangda Group, Top Tier Facade, and more, showcasing our extensive experience in aluminum profile wall curtain production. We continuously innovate and improve our solutions to provide our customers with the most suitable aluminum wall curtain options for their projects. Ruiqifeng prides itself on being a dependable partner. With the principles of integrity, quality, and innovation as our foundation, we are dedicated to achieving mutual growth with our customers. Whether you require personalized aluminum profiles for wall curtain or other custom extrusion products, we are committed to delivering satisfactory solutions. If you are interested in our products or have any inquiries, please do not hesitate to reach out to us. We eagerly anticipate the opportunity to collaborate with you! PriceList for Aluminum Radiators Testing Machine - Black Anodized Aluminum Extruded Heat Sink – Ruiqifeng , The product will supply to all over the world, such as: French, panama, Czech Republic, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.